Used Foil Container Machine Inspection Guide | Mold & Clearance Check

We often see startups browsing auctions for Used Aluminum Foil Container Machines to save capital. The price tag looks attractive—often 40% less than a new line.

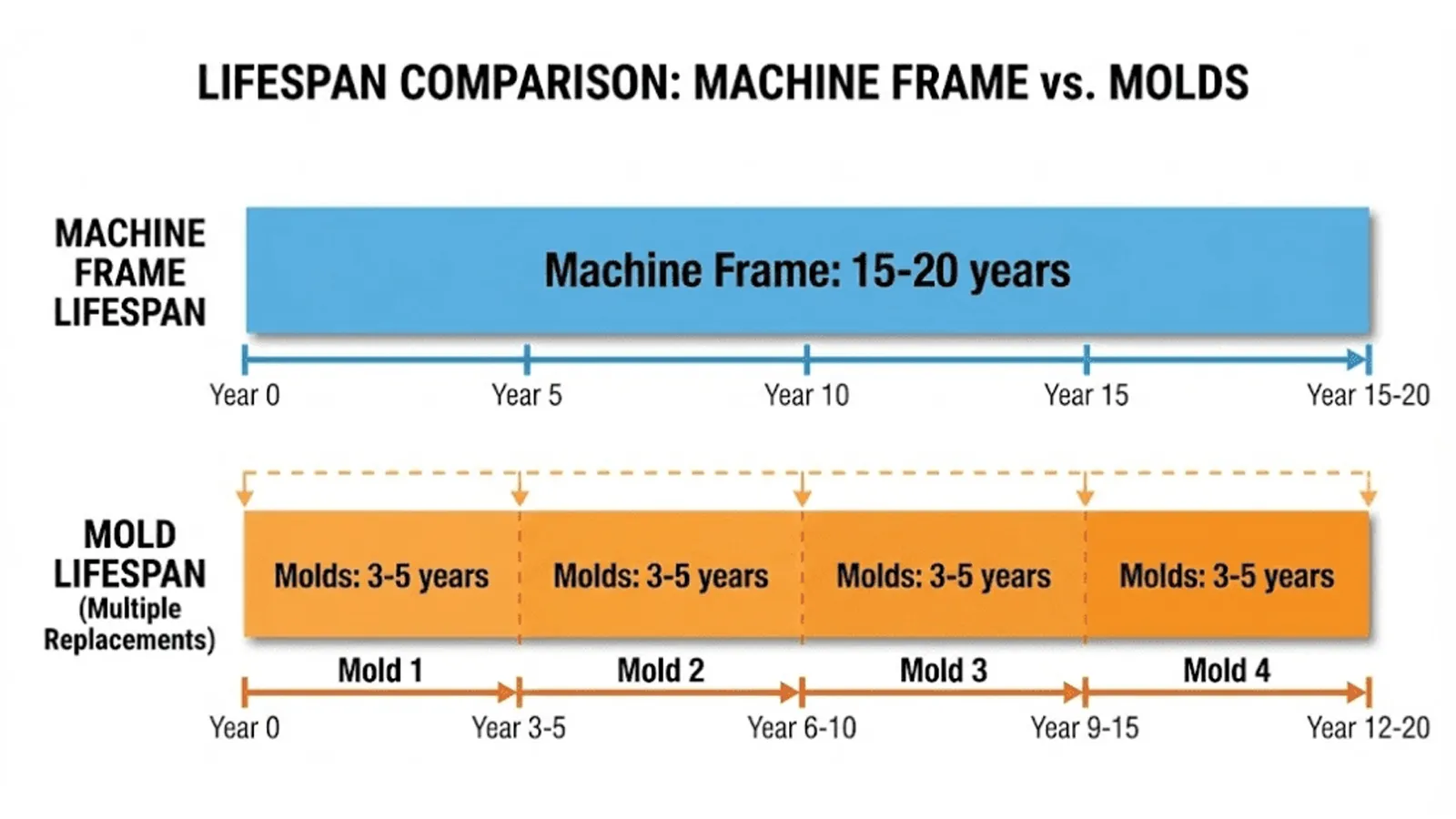

But here is the engineering reality: Machines last 20 years. Molds only last 3-5 years.

Buying a 10-year-old press with a well-maintained mold is a smart investment. Buying a 3-year-old press with a worn-out die is a financial trap. As a manufacturer of these machines, Newtop Machine shares the insider inspection checklist to help you avoid buying someone else’s problem.

1. The "Mold First" Rule

Most buyers obsess over the "Manufacture Date" on the machine nameplate. This is the wrong metric.

A standard foil container mold has a service life of roughly 10 million to 20 million strokes. At a typical production speed of 60 strokes/minute, a mold running two shifts a day will reach its end of life in just 3 to 4 years.

The Math of the Mistake:

If you buy a used machine for $30,000, but the mold is worn out, you must immediately spend $15,000 - $20,000 on a new tool. Suddenly, your "cheap" used machine costs $50,000—dangerously close to the price of a brand-new Newtop machine with a warranty.

2. How to Inspect Mold Condition (Technical Steps)

Don't trust the seller's word. Bring a set of feeler gauges and perform these checks:

Step A: Measure Die Clearance

The gap between the upper punch and the lower die (cutting clearance) determines the cut quality.

Standard Tolerance: 0.02mm - 0.04mm.

The Test: Insert the feeler gauge at four points around the die perimeter. If the gap exceeds 0.06mm, the die is severely worn. You will face constant Edge Burr issues that are impossible to fix without re-machining.

Step B: Check Guide Pillars

Shake the mold base physically. If there is visible play in the guide pillars, the mold stability is gone. This leads to "double-cutting" and will destroy your press bearings over time.

3. Test Run Assessment: The "5% Rule"

Never buy a machine without seeing it run with foil. Dry running (without material) hides 90% of the problems.

Request a 15-minute continuous run and watch for:

- Speed Drop: Does the machine hesitate or slow down under load? A 5% drop from rated speed suggests hydraulic pump wear or motor fatigue.

- Product Consistency: Stack 50 finished containers. Are they perfectly vertical? If the stack leans like the "Tower of Pisa," the rim formation is uneven.

- Scrap Ejection: Does the waste foil flow out smoothly, or does it jam? Jamming often indicates dull cutters.

4. The Hidden Costs of "Secondhand"

When calculating your ROI, you must add the "Restoration Tax" to the sticker price. Industry data suggests you should budget for:

| Cost Item | Estimated Expense | Why? |

|---|---|---|

| Rigging & Installation | $1,000 - $3,000 | No factory warranty means you pay for setup. |

| Spare Parts Kit | $1,500+ | Solenoids and seals usually need immediate swap. |

| Mold Refurbishment | $5,000 - $15,000 | Sharpening or replacing core die steel. |

| Total Hidden Cost | ~$10,000+ | Add this to your purchase price. |

5. Documentation: The Red Flag

Ask for the Maintenance Log.

A 10-year-old machine with records of regular oil changes and bearing replacements is a gem. A 3-year-old machine with zero paperwork is a gamble. If the seller cannot prove when the last spindle calibration was done, walk away.

Summary: Used vs. Newtop?

If you find a well-maintained used machine with good molds for under $20,000, buy it. It is a good start.

However, if the used machine costs $35,000 and needs a new mold, you are better off buying a Brand New Newtop Machine. You get:

- Zero wear on tooling.

- Latest H-Frame rigidity for Smooth-Wall production.

- 1-Year Warranty and free spare parts.

Not sure if a used deal is worth it? Send us the photos and specs. We will give you an honest appraisal and compare it with a new machine quote. Get a Free Assessment.