- [email protected]

- Ruian City, Zhejiang Province, China

Engineering Proposal: 100 Million PS/PP Cup Production Ecosystem

A dedicated **Dual-Line Servo Thermoforming** strategy to ensure 24/7 continuous output. Integrated with **8-Color CI Gearless Flexo** for photorealistic dairy packaging (solving the "Sour Cream" print challenge) and a cost-saving **Universal Lid** manufacturing line.

View Full StrategyDear Ryan,

Our company is evaluating suppliers for a complete production line for polystyrene (PS) and polypropylene (PP) cups.

Requirements:

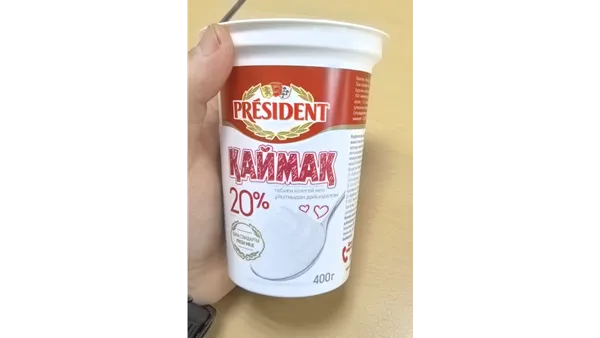

- 50M pcs — 400 ml cups (11.78 g)

- 50M pcs — 260 ml cups (7.05 g)

- Universal Lid for both cups (2.67 g)

- 8-color printing capability required.

Please provide a complete commercial proposal.

The Challenge: Photorealistic Printing

The client specifically identified that standard 6-color dry offset printing creates grainy textures on white dairy imagery.

Why Standard Machines Fail:

- ✖ Dry Offset lacks dot precision for smooth gradients.

- ✖ Curved surface printing distorts fine details.

The Perfect Solution: Gearless CI Flexo

- ✔ Gearless CI Flexo Press: Servo drive eliminates vibration, ensuring photorealistic dots.

- ✔ Pre-Printing Advantage: Printing on the flat sheet before forming guarantees zero distortion on the "Sour Cream" design.

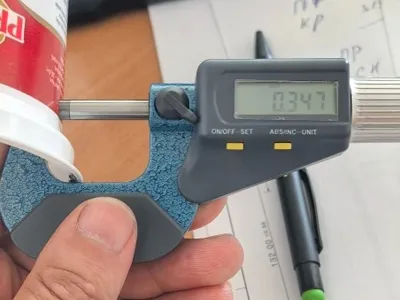

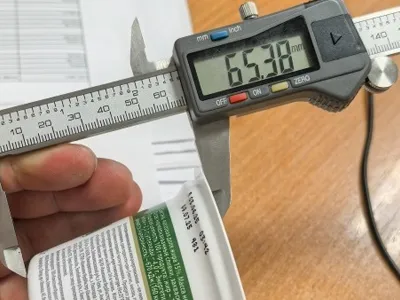

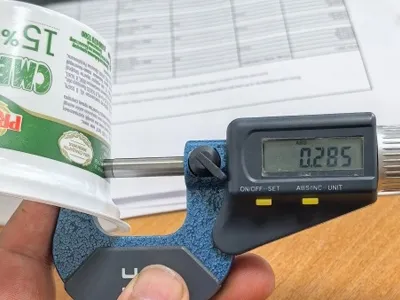

1. Engineering Analysis

We analyzed the technical photos to calculate the exact draw ratio and mold cavity layout.

Product A: 400ml

Target: 11.78g ±0.2g

Product B: 260ml

Target: 7.05g ±0.1g

2. The Integrated Ecosystem Strategy

To ensure 100M annual output for both cups and lids with zero downtime, we propose a dedicated multi-line ecosystem.

Deep-Draw Servo Line

Powered by our flagship Cup Makers, optimized for 11.78g cups.

Technology: Cam-Driven + Plug Assist

High-Speed Servo Line

Dedicated setup for high-cycle shallow draw production.

Technology: High-Speed Forming

Universal Lid Production Line

To match the 100M annual cup volume, we integrate our high-precision Lid Machines. One line handles the 2.67g universal lid for both cup sizes.

- ✔ Capacity: 30,000+ lids/hour (Matches total cup output)

- ✔ Precision: ±0.1mm fitment tolerance for leak-proof seal.

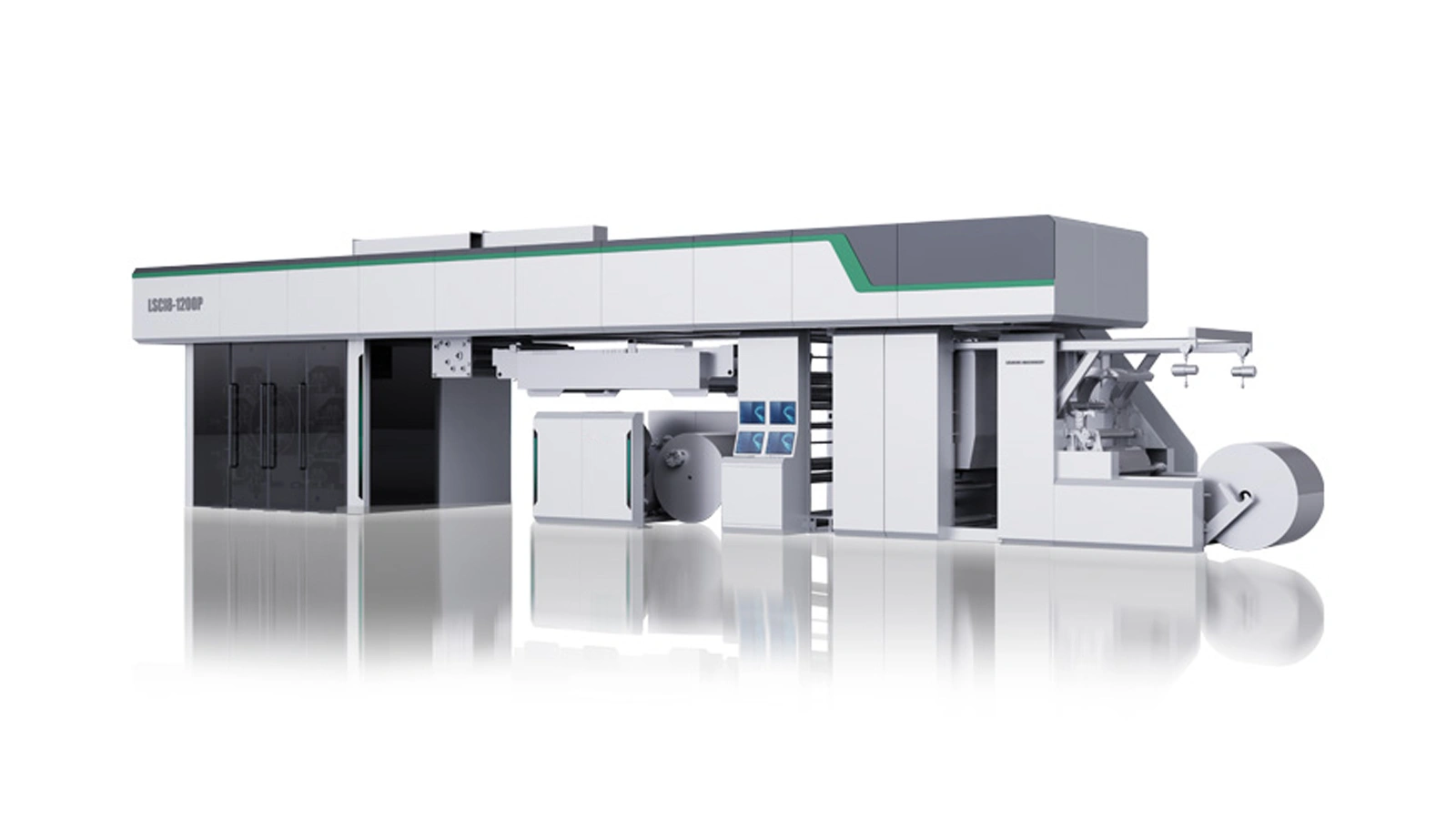

8-Color CI Gearless Flexo

The 8 Color Gearless CI Flexo Press is the only solution for the "Sour Cream" photorealistic design. We print on the sheet BEFORE forming.

- ✔ Gearless Servo: No vibration, perfect dots.

- ✔ Central Impression: Perfect registration for PP.

See It In Action

Watch our High-Speed Thermoforming Line running at 25,000 cups/hour.

Don't just take our word for it. Watch the NT-750 Servo Cam in full operation processing PP material.

- ✔ Zero Vibration: Cam-drive ensures smooth running.

- ✔ Auto-Stacking: Reduces labor costs by 60%.

- ✔ Real Material: Testing with 1.2mm PP Sheet.

Get This Line Configuration

3. Secure Milestones & Payment

We operate on a "Performance-Based" payment structure. You only pay the balance after the machine proves its capability.

Contract signed via T/T or Alibaba Trade Assurance. Manufacturing begins immediately.

45-60 Days manufacturing time. Weekly video reports provided to track progress.

Critical Step: We run your material for 8 hours continuously. You approve the quality via video or in-person visit.

Paid only AFTER successful FAT. Machine is crated and shipped.

Let's Build Your Factory

Copy my contact info to chat directly on WhatsApp or WeChat.