Starting a Foil Container Business? Read This Before Buying Machines

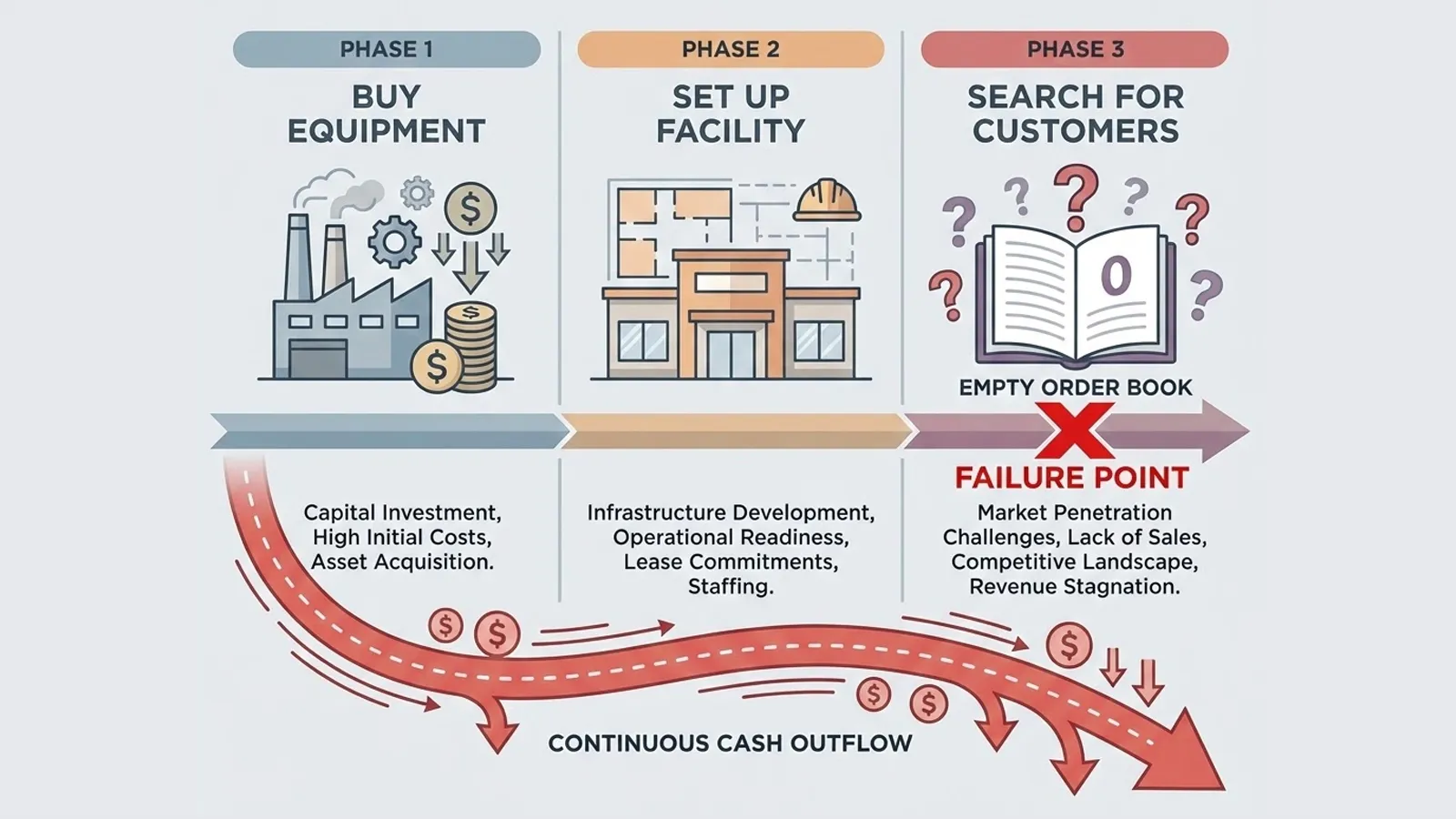

Forty-two percent of manufacturing startups fail not because their machines broke down, but because they built a factory for customers who didn't exist.

We often see enthusiastic entrepreneurs at trade shows asking about machine speeds and mold cavities, assuming that "if I build it, they will come." In the competitive packaging industry, this equipment-first mentality is a recipe for burning capital.

As a machinery manufacturer, we want you to succeed—because your growth is our growth. This guide outlines the proven startup path for an aluminum foil container business, prioritizing market validation before the machinery purchase.

Phase 1: Validate Your Local Market (Before You Spend a Dollar)

The global foil container market is huge ($3.65 billion), but that doesn't mean your local town needs another supplier. You must zoom in.

Step A: Identify the Gap

Your potential customers (restaurants, caterers, bakeries) already have a supplier. To win them, you need to solve a pain point. Call 20 local businesses and ask:

- "Are you happy with your current foil container supplier?"

- "Do you face stock-outs during holiday seasons?"

- "Is the current pricing hurting your margins?"

If they complain about long lead times or inconsistent quality, you have found your market entry point.

Step B: Secure "Soft" Commitments

Don't guess what sizes to make. Ask a local bakery: "If I can supply this specific tart pan at 5% less than your current price, would you buy from me?"

If they say yes, you have your first product specification. This "Letter of Intent" approach validates your revenue model before you even own a machine.

Phase 2: The Financial Reality Check

Equipment is just the entry ticket. The real challenge is cash flow.

Working Capital Calculation

In B2B manufacturing, you often pay for raw materials (aluminum coils) upfront, but your customers pay you on "Net 30" or "Net 60" terms.

The Trap: You produce in January, deliver in February, but get paid in April. You need enough cash reserves to fund 3 months of operations (material, labor, electricity) without revenue.

Resource: Use our Aluminum Container Cost Analysis to estimate your raw material and scrap recovery values.

Phase 3: Selecting the Right Equipment

Now that you know what you are making and who is buying it, you can choose the machine.

Don't Overbuy Capacity

If your pre-orders total 50,000 containers a month, buying a high-speed line capable of 3,000,000/month is financial suicide.

- For Startups: We recommend a robust, semi-automatic press (like the SE Series). It lowers your initial CAPEX and is easier to learn.

- For Expansion: Once you hit 70% capacity utilization, that is the trigger to upgrade to a fully automatic line with auto-stackers and scrap balers.

The Mold is Key

Your business is selling containers, not machines. The Mold determines the product. Based on your Phase 1 research, select the top 2-3 most popular sizes (e.g., 450ml Rectangular, 9-inch Round) as your starter molds. Don't try to launch with 10 different sizes; the setup costs will drown you.

Phase 4: Facility & Compliance

Before the machine arrives, your factory must be ready.

- Power: Most industrial presses require 3-Phase, 380V power. Ensure your workshop is wired for industrial loads.

- Space: You don't need a massive warehouse. A 150-300 sqm facility is often sufficient for a single line, raw material storage, and finished goods packing.

- Hygiene (FDA/HACCP): You are making food-contact packaging. Your facility needs clean epoxy floors, pest control, and a lubrication system that prevents oil contamination.

Phase 5: Your First 90 Days

The machine is installed. Now what?

- The "Learning Curve": Expect the first month to be slow. Your operators need to learn how to change coils and adjust the press.

- Quality First: Implement strict QC immediately. If your first batch has sharp burrs or oil spots, you will lose those early customers forever.

- Reinvest: Don't take profit out yet. Reinvest early revenue into building your inventory of popular sizes so you can offer "Same Day Delivery"—your biggest advantage over distant competitors.

Summary: The Sequence of Success

Successful entrepreneurs follow this order:

1. Find Customer -> 2. Define Product -> 3. Buy Machine.

If you have validated your local market and are ready to choose the equipment that matches your actual demand, Newtop Machine is here to help. We don't just sell machines; we help you plan your factory layout and calculate your ROI.