Rotary Die Cutting Guide Cutting Film vs Paper & Troubleshooting

The "Universal Cutter" Myth

One of the most dangerous misconceptions in label converting is the idea that "a die is a die."

We often see operators trying to use the same flexible die plate to cut a 20-micron PET film that they used for 80gsm semi-gloss paper. The result? Either they cut through the liner (causing web breaks), or they don't cut deep enough (causing waste matrix breaks).

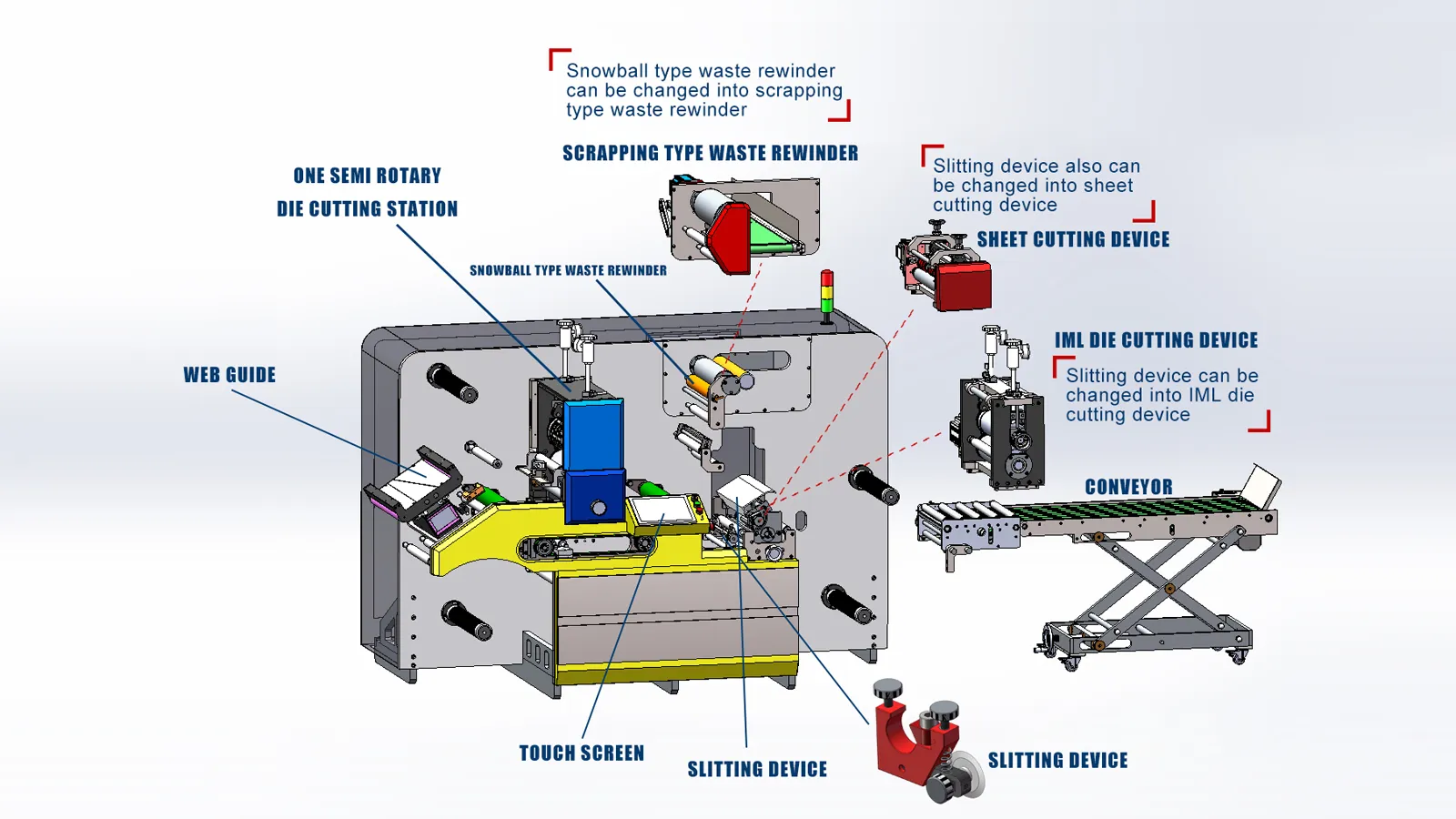

At Newtop Machinery, we engineer our Rotary Die Cutting Machines to handle diverse substrates, but the machine is only as good as the tooling and the setup. Cutting multi-materials requires understanding the physics of the "Gap." Here is the engineer’s guide to mastering the mix.

1. The Physics: Paper Compresses, Film Snaps

Why is switching materials so hard?

- Paper (Crush Cut): Paper fibers need to be crushed to separate. You can apply heavy pressure, and the liner (usually glassine) is forgiving.

- Film (Burst Cut): Plastic films like BOPP or PE are tough. They don't crush; they need to be severed. However, the synthetic liner underneath is often thinner and harder.

The Challenge: The margin for error on film is microscopic. If your "Anvil Gap" (the space between the blade tip and the anvil cylinder) is off by just 3 microns, you will slice the liner.

2. Tooling Strategy: Stop Guessing, Start Measuring

If your factory runs both paper and film, you need a strict tooling strategy.

Blade Angles Matter:

You cannot use a standard 60° paper blade for film. Film requires a sharper, steeper angle (often 40° or 50°) to penetrate the plastic without requiring excessive pressure that destroys the liner.

The "Adjustable Anvil" Solution:

For high-mix shops, we highly recommend equipping your die station with an Adjustable Anvil Cylinder (Gap Master). This allows the operator to mechanically adjust the gap by +/- microns on the fly.

Why? Because as the machine heats up, metal expands. A gap that was perfect at 8:00 AM might be too tight by 12:00 PM. An adjustable anvil solves this without stopping the press.

3. Tension Control: The Invisible Variable

Many "cutting" problems are actually "tension" problems.

- Infeed Tension: If the web enters the die station too loose, the material will shift, causing the die to cut in the wrong place (registration error).

- Waste Matrix Tension: This is the #1 cause of downtime. If the waste rewind tension is too high, the delicate matrix grid will snap. If it's too low, the labels will lift up with the waste (flying labels).

How We Fix It: On our advanced finishing lines, we use Servo-Driven Waste Winders with torque feedback. The machine "feels" the tension of the waste matrix and adjusts speed automatically to prevent snapping, even on complex shapes.

4. Troubleshooting: The Engineer’s Checklist

Before you call for service, run through this diagnostic list.

Problem A: The Liner is Cutting Through (Web Breaks)

Diagnosis: Pressure is too high, or the die is too "tall."

Action:

1. Reduce pressure gauges to zero and re-engage slowly.

2. Check the "Bearer Rings" on the magnetic cylinder. If they are dirty, the cylinder sits higher, forcing the operator to over-pressure. Clean them immediately.

Problem B: Labels are "Flying" (Sticking to Waste)

Diagnosis: The adhesive is too aggressive, or the cut isn't deep enough.

Action:

1. Check the blade sharpness.

2. Static Electricity is a common culprit with film. Ensure your anti-static bars are positioned after the die station to neutralize the charge holding the label to the waste.

Problem C: Uneven Cutting (Cuts on Left, Not Right)

Diagnosis: The die station is uneven (not parallel).

Action: This is a machine calibration issue. Use pressure-sensitive carbon strip tape (carbon paper test) to visualize the impression footprint and adjust the levelling screws on the die station.

Conclusion: Precision Protects Profit

Die cutting is the final step. Scrapping a roll here means you've wasted the material, the ink, and the print time. It is the most expensive place to fail.

Don't rely on luck. Invest in the right tooling geometry and machines with precise gap control.

Need a die-cutting test on your specific material? Send us your sample rolls. We will run them on our machine and send you a video of the results.