Technical Specifications

| Type | NTP-HBH paper food box forming machine |

|---|---|

| Suitable material | 200-600gsm white card board, PE coated paper, Kraft paper, corrugated paper |

| Production speed | 100-300pcs/min(double lane, different paper box shapes, the speed is different) |

| Blank paper size |

Length 100-450mm, feeding Width 100-450mm, Height 15-200mm,Angle 5-40° |

| Blank paper weight | Max. 3mm for corrugated paper |

| Total power | 7KW |

| Total weight | 2600KGS |

| Packing dimension | 3600*1900*1700mm |

| Power source | 380V, 50HZ |

| Our machines can be customized according to customer needs, offering a variety of box types rather than just a single option. | |

Product Description

Product Overview: The All-in-One Fast Food Box Solution

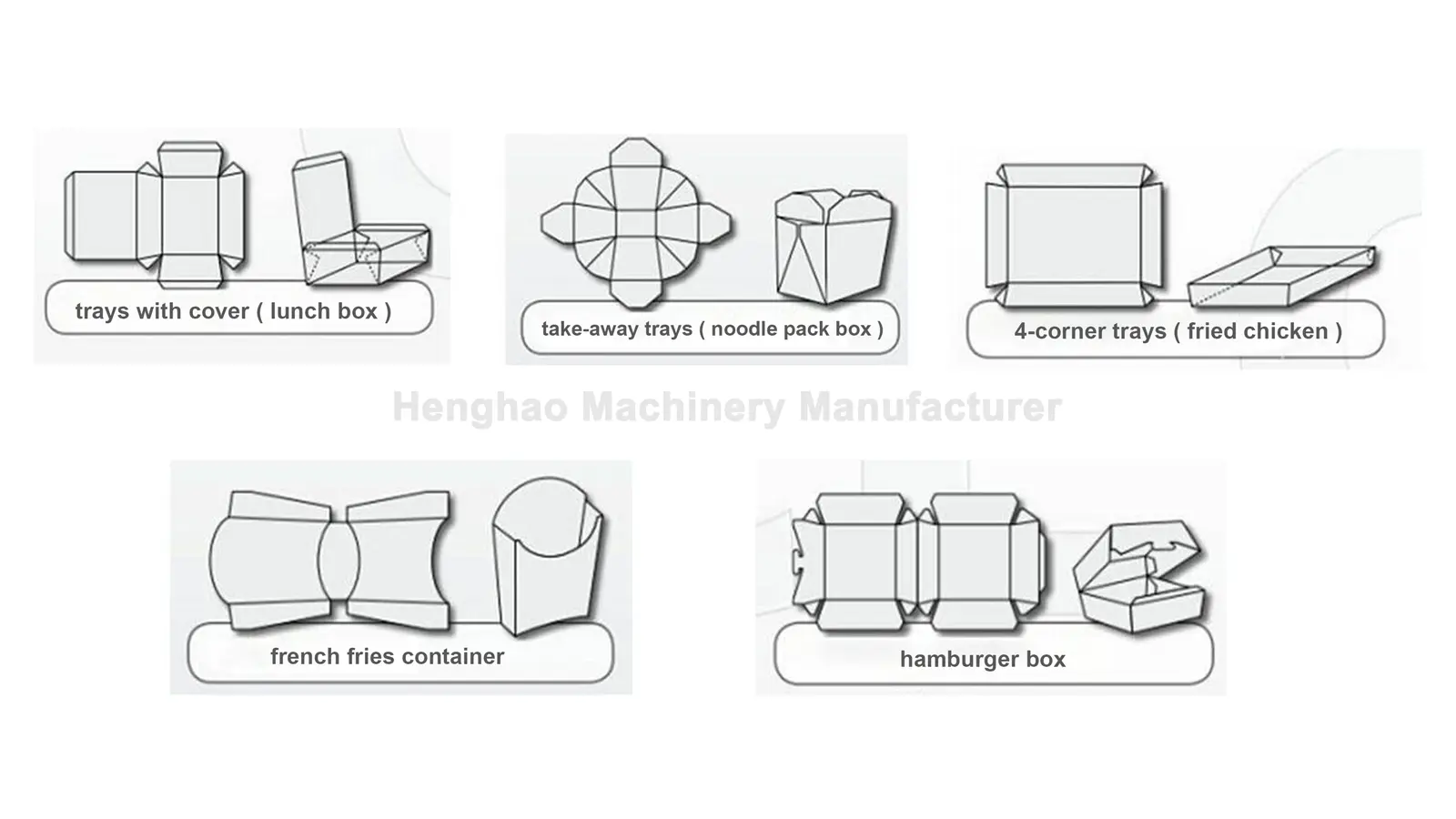

The NTP-HBH Hamburger Box Making Machine is an advanced Carton Erecting Machine designed to meet the diverse packaging needs of the fast-food industry. Unlike machines limited to a single shape, the NTP-HBH is highly versatile. It automates the entire process of feeding, gluing, forming, and stacking to produce a wide variety of eco-friendly paper containers, including Hamburger Boxes, French Fry Scoops, Fried Chicken Boats, and Takeaway Lunch Boxes.

Key Features & Production Capabilities

- High-Speed Output: Capable of running at speeds between 60 to 160 pieces per minute (depending on box size), significantly outperforming manual folding and reducing labor costs.

- Wide Material Compatibility: Engineered to handle a broad range of materials, from standard Cardboard/Ivory Paper (200-600g/m²) to sturdy Corrugated Paper (up to 1.5mm thick). This allows you to produce both lightweight snack boxes and heavy-duty burger clamshells on one machine.

- Water-Based Glue System: The precise Glue Unit applies standard water-based adhesive (cold glue), which is cost-effective, food-safe, and ensures a strong bond for the box corners.

- Automated Workflow: Features a fully integrated line: Paper Feeding Unit → Gluing Unit → Forming Unit → Finished Product Collection & Counting Unit. The machine automatically counts and stacks the finished boxes, ready for immediate packing.

- Quick Size Adjustment: The machine design allows for easy mold changes and adjustments, giving you the flexibility to switch between producing small Fry Boxes and large Burger Boxes with minimal downtime.

Ideal Applications

The NTP-HBH is the standard equipment for producing packaging for:

- Burgers & Sandwiches: Clamshell boxes and trays.

- Snacks: French fry scoops, Chips boxes, Nugget trays.

- Takeaway Meals: Open food boats and Asian food pails.

Start Your Packaging Line: Need a reliable machine for burger boxes? Contact Newtop Machinery to get a quote and production video for the NTP-HBH.