Technical Specifications

| Type | NTP-CHX |

| Production capacity | 12-15 pcs/min |

| Maximum paper feeder size | 300 x260mm |

| Max Paper Convey Width | 260mm |

| Suitable Material | 250-400g/㎡ (PE Coated paper) |

| Rated Power | 15 KW |

| Total Weight | 1000KGS |

| Packing Dimension(without conveyor) | 2300(L)*1100(W)*1900(H) mm |

| Working Air Source |

Air pressure 0.5Mpa (Need to buy compressor Gas volume:0.2-03 m3/Min |

Product Description

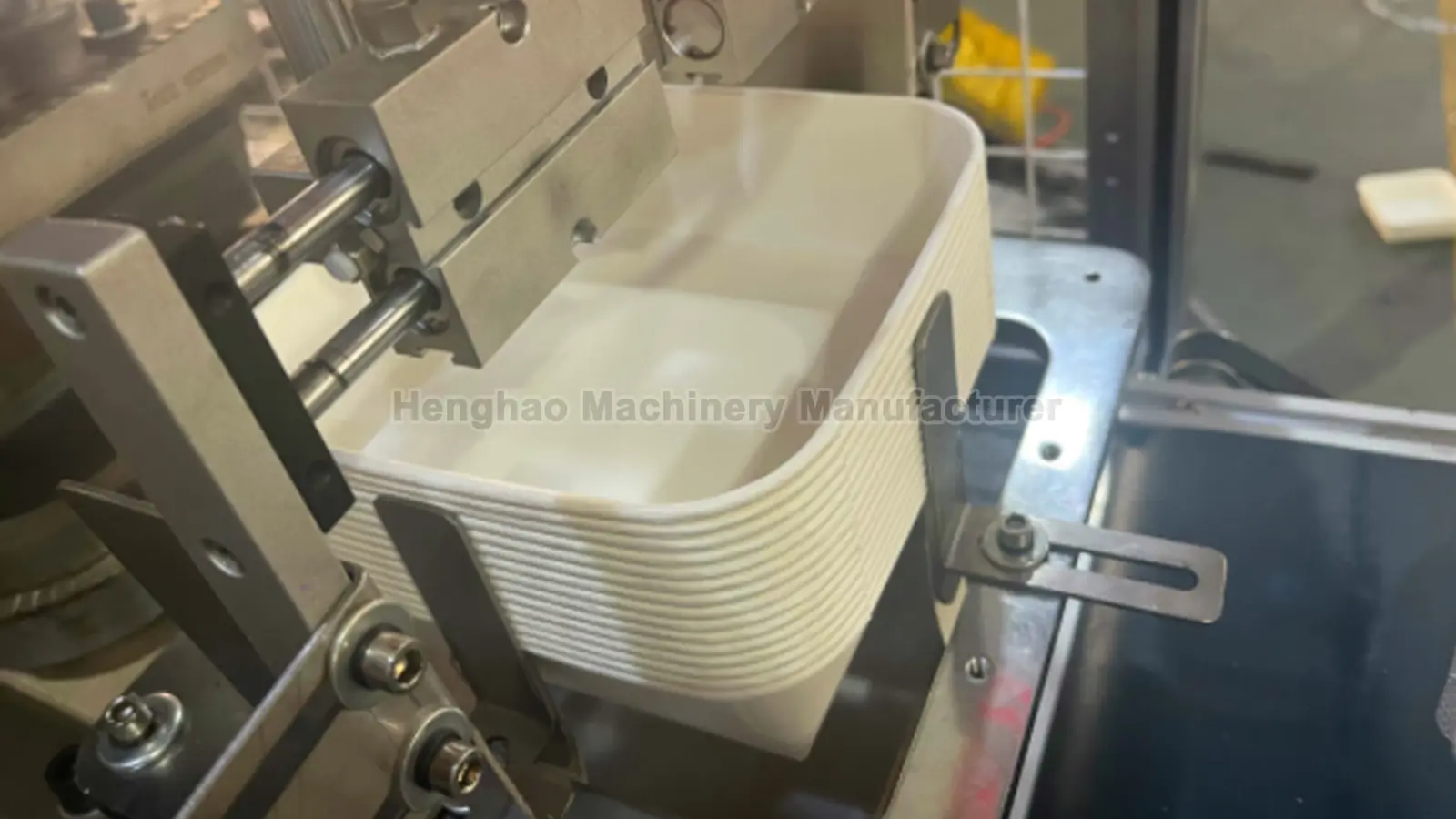

Product Overview: Premium Trays with Rolled Rims (Curling)

The NTP-CHX Paper Tray Food Packing Box Forming Machine is a specialized automatic solution designed for the high-end food packaging market. Unlike standard carton erectors that simply fold paper, the NTP-CHX features a unique Three-Course Top Curling System. This technology rolls the edge of the square box into a smooth, rigid rim (similar to a paper cup), making it perfect for Sushi Boxes, Salad Trays, and Premium Takeout Bowls that require a tight-fitting lid.

Key Features & Hydraulic Power

- Top Curling Technology: The machine performs a precise curling operation on the tray's edge. This rolled rim not only looks premium but also significantly increases the box's structural rigidity and ensures a secure snap-fit with plastic lids.

- Hydraulic Forming System: Curling a square box requires immense pressure. The NTP-CHX is equipped with a powerful Hydraulic System to provide the necessary molding force, ensuring every tray is formed perfectly without spring-back.

- Servo Drive Precision: Utilizes Servo Drive Technology for paper feeding and positioning. This ensures the paper is aligned accurately before the heavy hydraulic mold comes down, minimizing waste.

- Eco-Friendly & Efficient: Designed to work with PE Coated Paper (250-400g/m²). It automates the entire process: feeding, forming, curling, and outputting, allowing one operator to manage the production line easily.

Ideal Applications

The NTP-CHX is the machine of choice for producing high-value packaging:

- Sushi & Sashimi Boxes: Rectangular trays with rolled edges for a premium look.

- Salad Bowls: Square or rectangular bowls that need to be leak-proof and sturdy.

- Fruit Trays: Strong trays for packaging fresh fruit in supermarkets.

Target the Premium Market: Don't just make boxes, make premium trays. Contact Newtop Machinery to see the curling quality of the NTP-CHX.