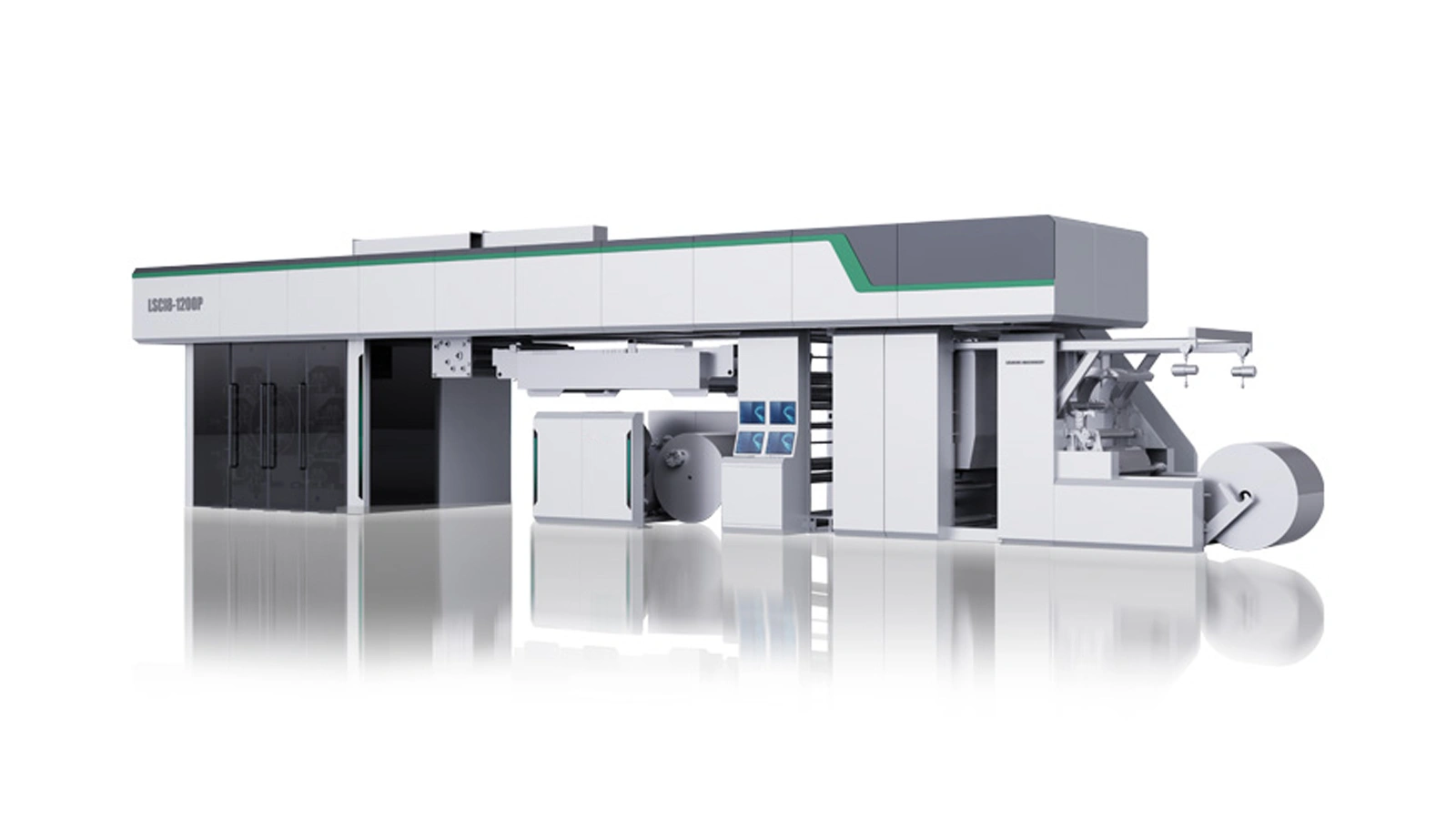

Technical Specifications

| Model | NTPG-81200 |

| Number of Colors | 8 Colors |

| Max. Material Width | 1200 mm |

| Max. Printing Width | 1160 mm |

| Mechanical Speed | 450 m/min |

| Printing Speed | 350 - 400 m/min (Depending on material/design) |

| Applicable Materials | Paper, PE, PET, BOPP, PVC, Breathable Film |

| Printing Repeat Length | 400 mm - 800 mm |

| Plate/Anilox Type | Sleeve Type (Cantilever) |

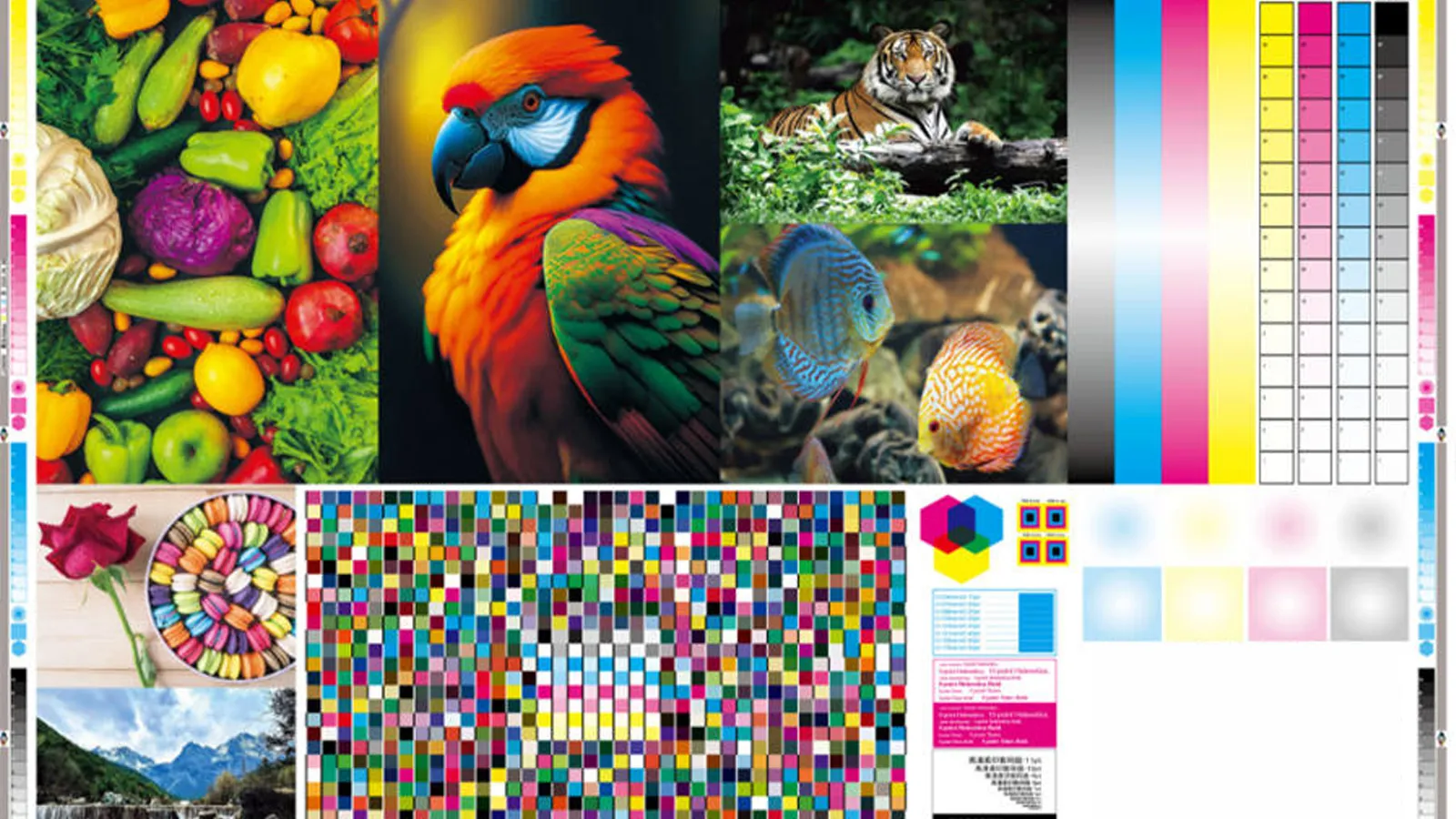

| Registration Precision | ±0.08 mm |

| Unwind / Rewind Dia. | Φ800 mm |

| Drying Method | Electric Heating (Water-base or Solvent ink) |

| Plate Thickness | 1.14mm / 1.7mm / 2.84mm (Customizable) |

| Power Supply | 380V / 3PH / 50Hz or 60Hz |

Product Description

The NTPG-81200 8 Colors Full Servo Gearless Flexographic Printing Machine represents the pinnacle of Central Impression (CI) technology. Designed for high-end flexible packaging manufacturers, this machine abandons traditional gear transmission in favor of a Direct-Drive Servo System. This results in superior print quality free from "gear marks" and significantly lower maintenance requirements.

Speed and versatility are at the core of the NTPG-81200. Capable of running at 400m/min, it handles a wide range of substrates including heat-sensitive materials like PE, PET, BOPP, and breathable films. The integrated Sleeve Technology allows for rapid job changeovers, making it profitable for both long-run production and short-run versatility.

- Gearless Direct Drive: Full servo motors drive each print deck independently, eliminating gear backlash, vibration, and the need for lubrication maintenance.

- Sleeve System Technology: Both the printing cylinder and anilox roller utilize a lightweight sleeve type design. This allows operators to change print jobs quickly without heavy tools, reducing downtime by up to 60%.

- High-Speed Production: Mechanical speeds up to 450m/min with stable printing speeds of 350-400m/min, maximizing daily output.

- Non-Stop Operation: Features a Turret Unwind and Rewind system with automatic splicing, allowing for continuous production without stopping the machine.

- Intelligent Drying: Fully automatic frequency conversion control drying system (Electric heating) that adjusts airflow based on printing speed to save energy.

- Auto-Registration: The advanced vision system achieves fully automatic color registration, correcting deviations instantly.

Why Choose Gearless CI Technology?

Unlike stack presses or geared CI presses, the gearless servo design ensures absolute synchronization between the central drum and the print decks. This guarantees precise color registration (±0.08mm) even during acceleration and deceleration, significantly reducing material waste.