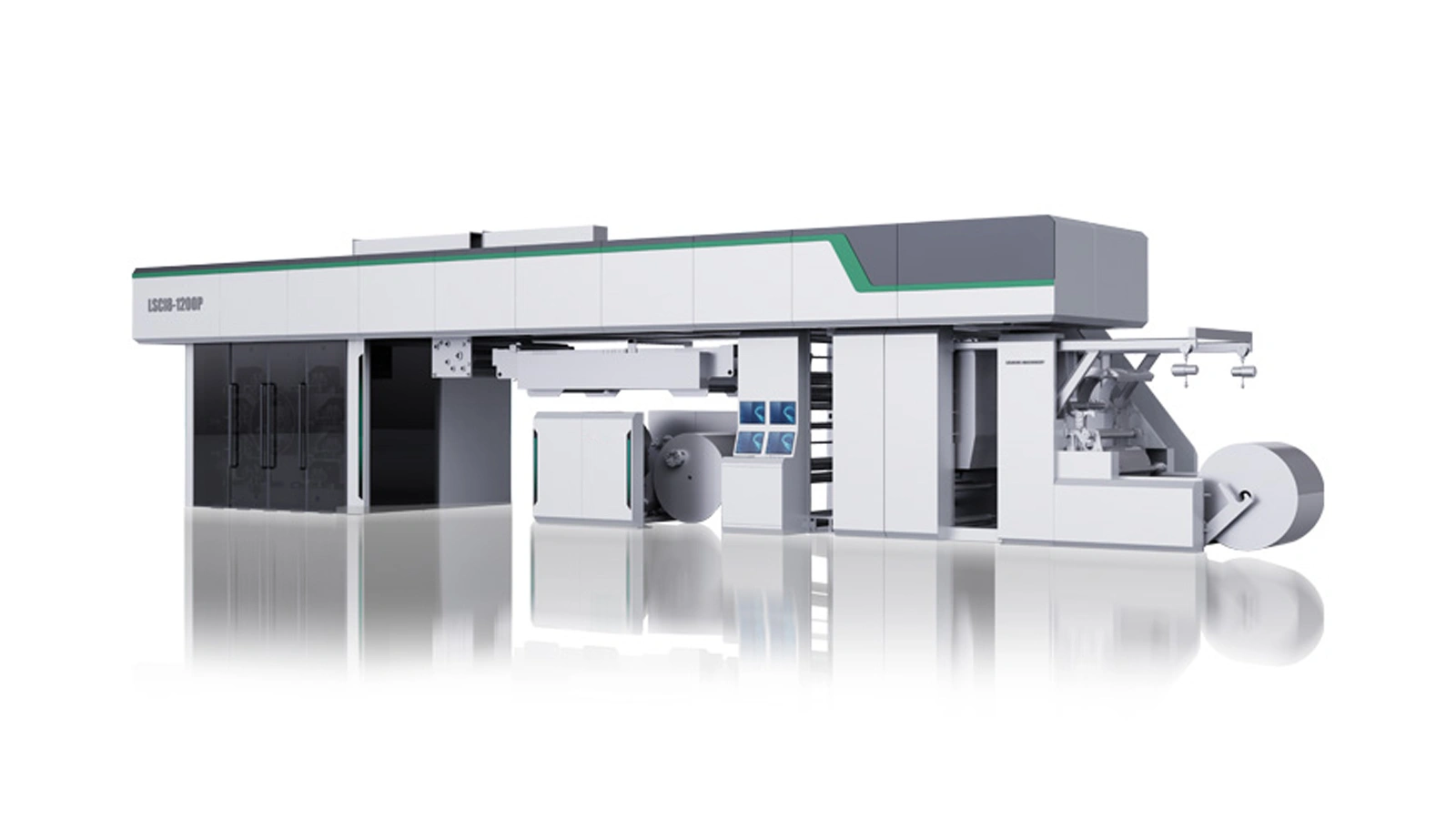

8 Color Gearless CI Flexo Press | 400m/min High Speed | NTPG-81200

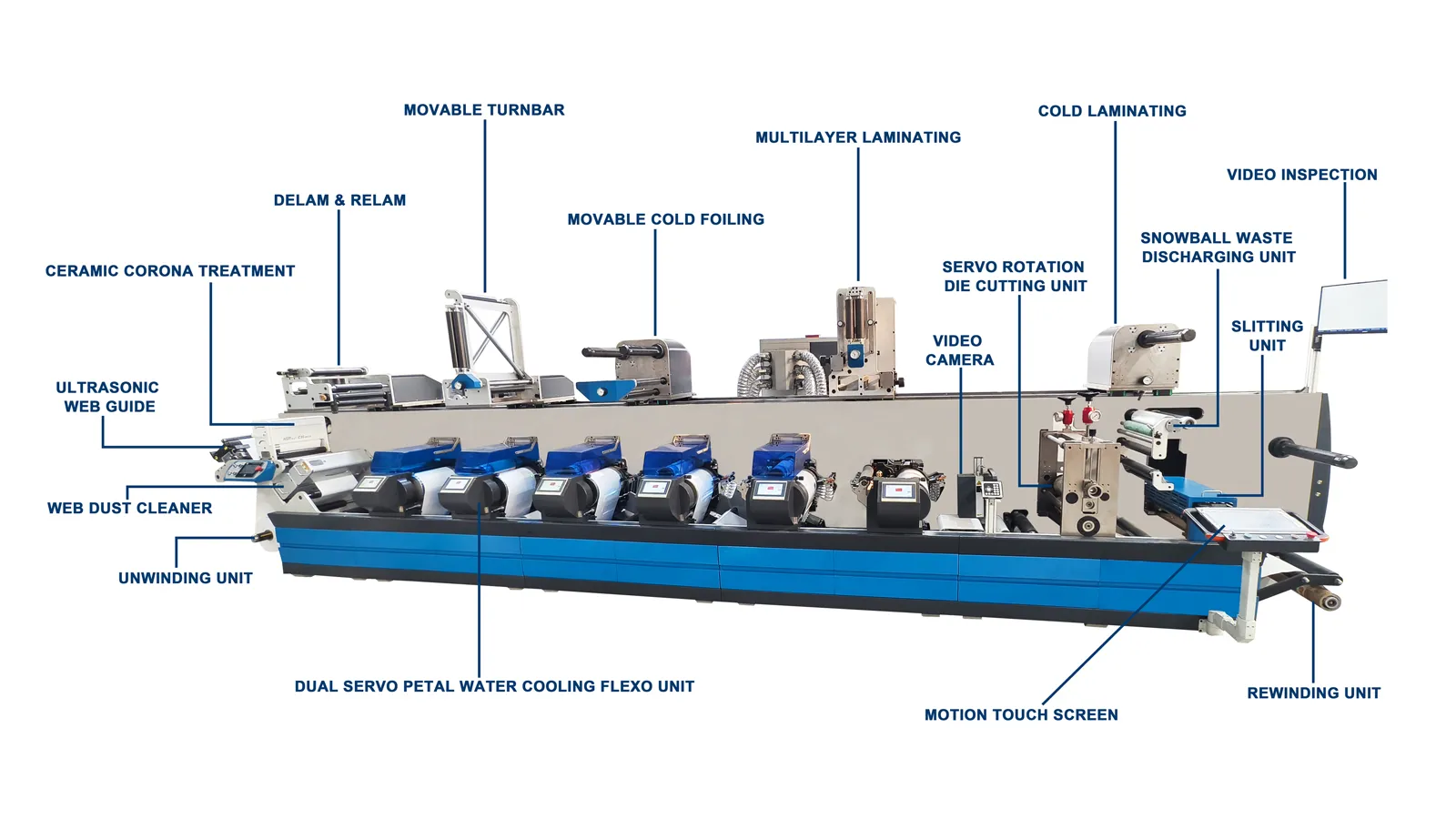

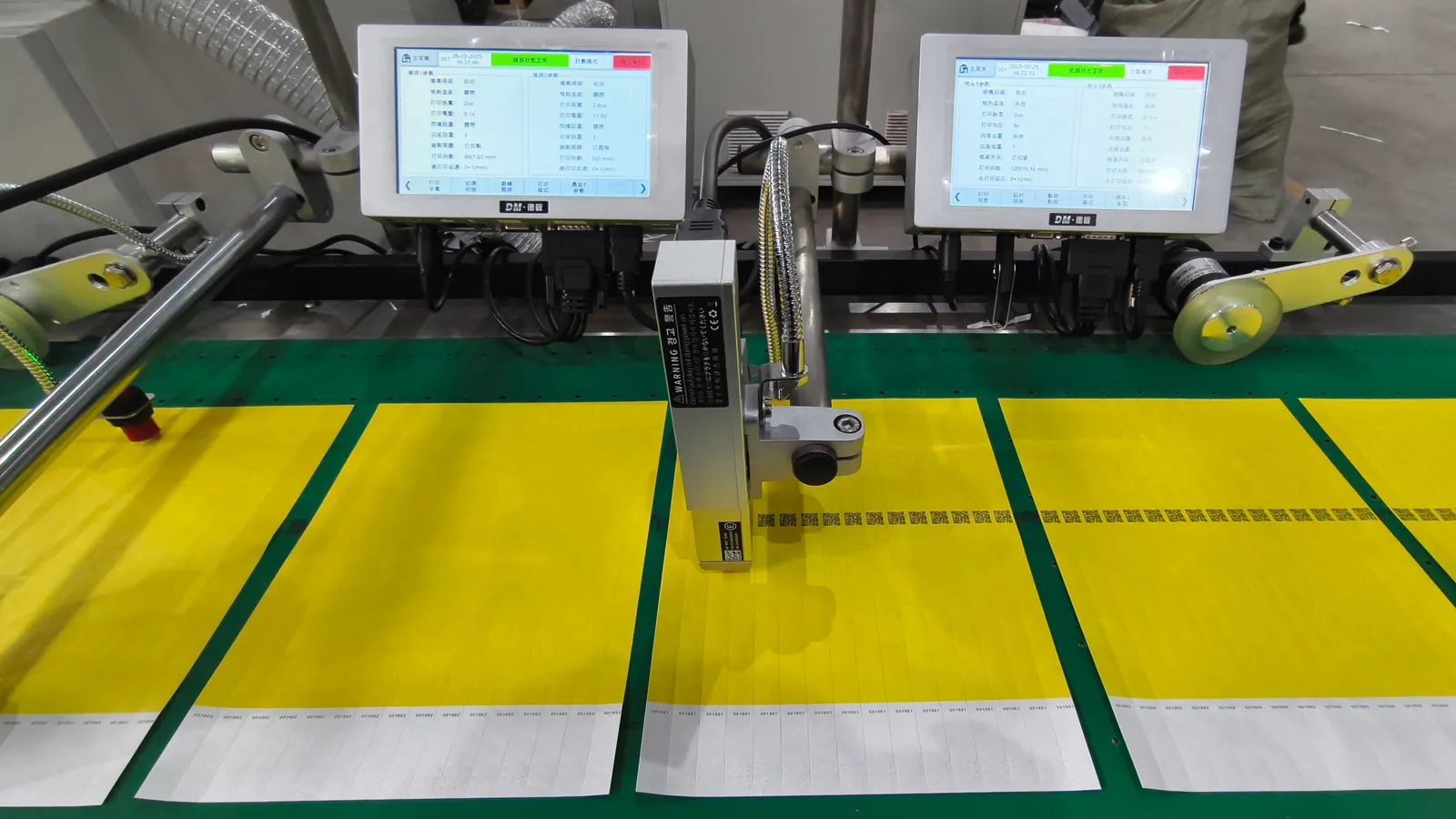

- Gearless Direct Drive

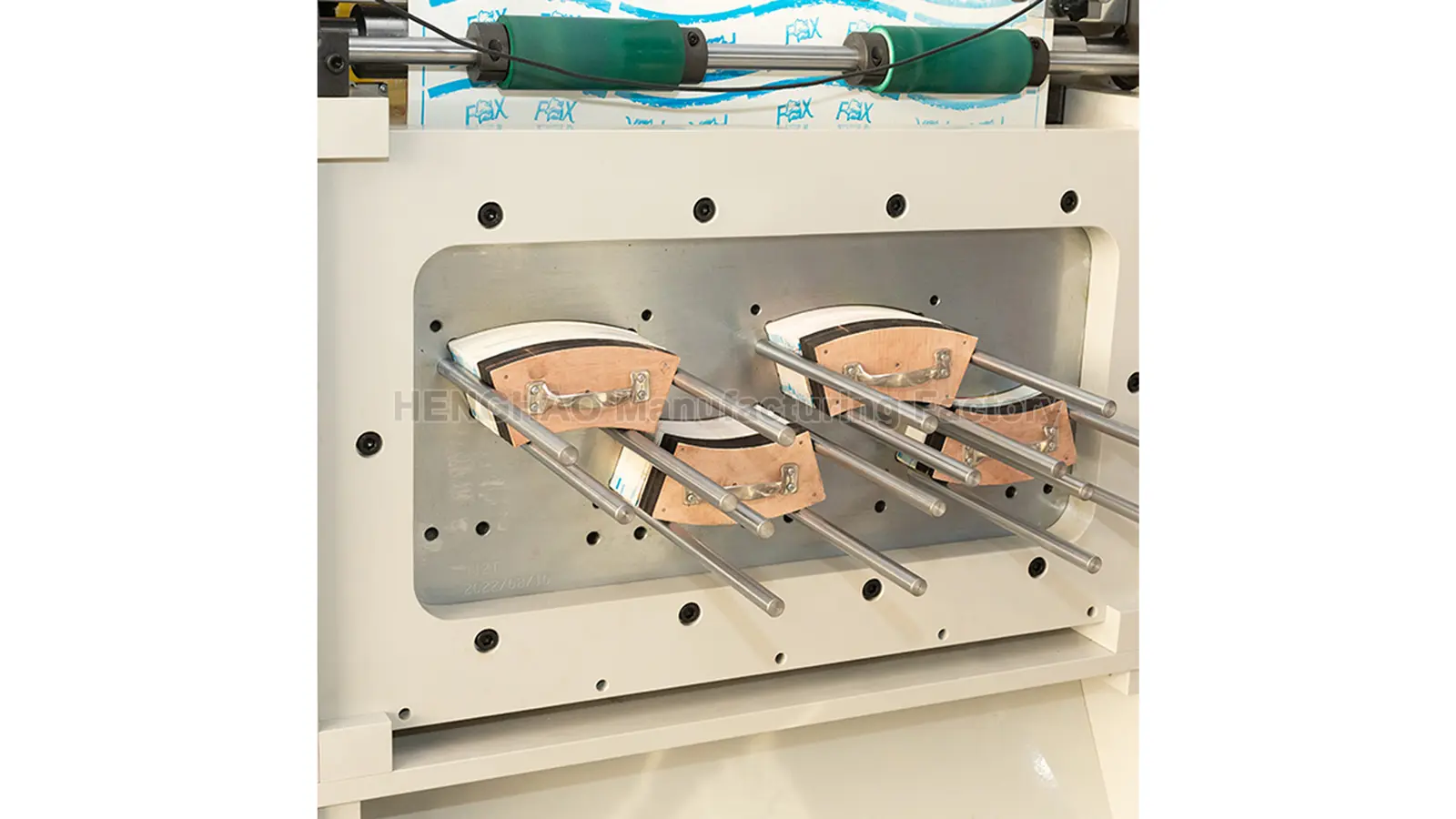

- Sleeve System Technology

- High-Speed Production

- Non-Stop Operation

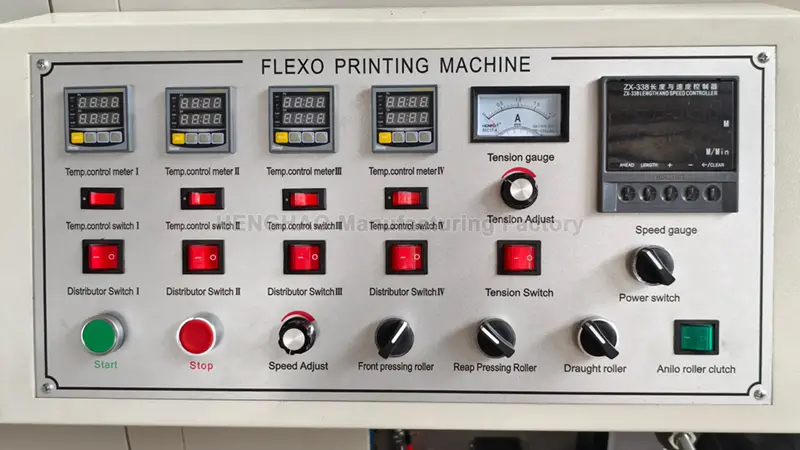

- Intelligent Drying

- Auto-Registration

(858)