Technical Specifications

| Specification | Details |

|---|---|

| Model | NJZ-370B |

| Max.Web width | 380mm |

| Max.Printing width | 370mm |

| Color quanity | 6 colors |

| Max.Unwind Diameter | 700mm |

| Max.Rewind Diameter | 700mm |

| Max.printing speed | 120m/min |

| Printing Precision accuracy | ±0.1mm |

| Rotary die cutting accuracy | ±0.15mm |

| Rang of printing | 228.6-600mm(72-189Z) |

| Max.label die cutting speed | 100m/min |

| Pre–registration | Color sensor |

| Thickness of material | 0.02mm—0.35mm |

| Power | 60KW 50/60HZ |

| Air Supply | 0.8KPA |

| Material: All Paper material ,Aluminum material ,some of unsupport film | |

| Our machines are customizable to fit your unique production needs. | |

Product Description

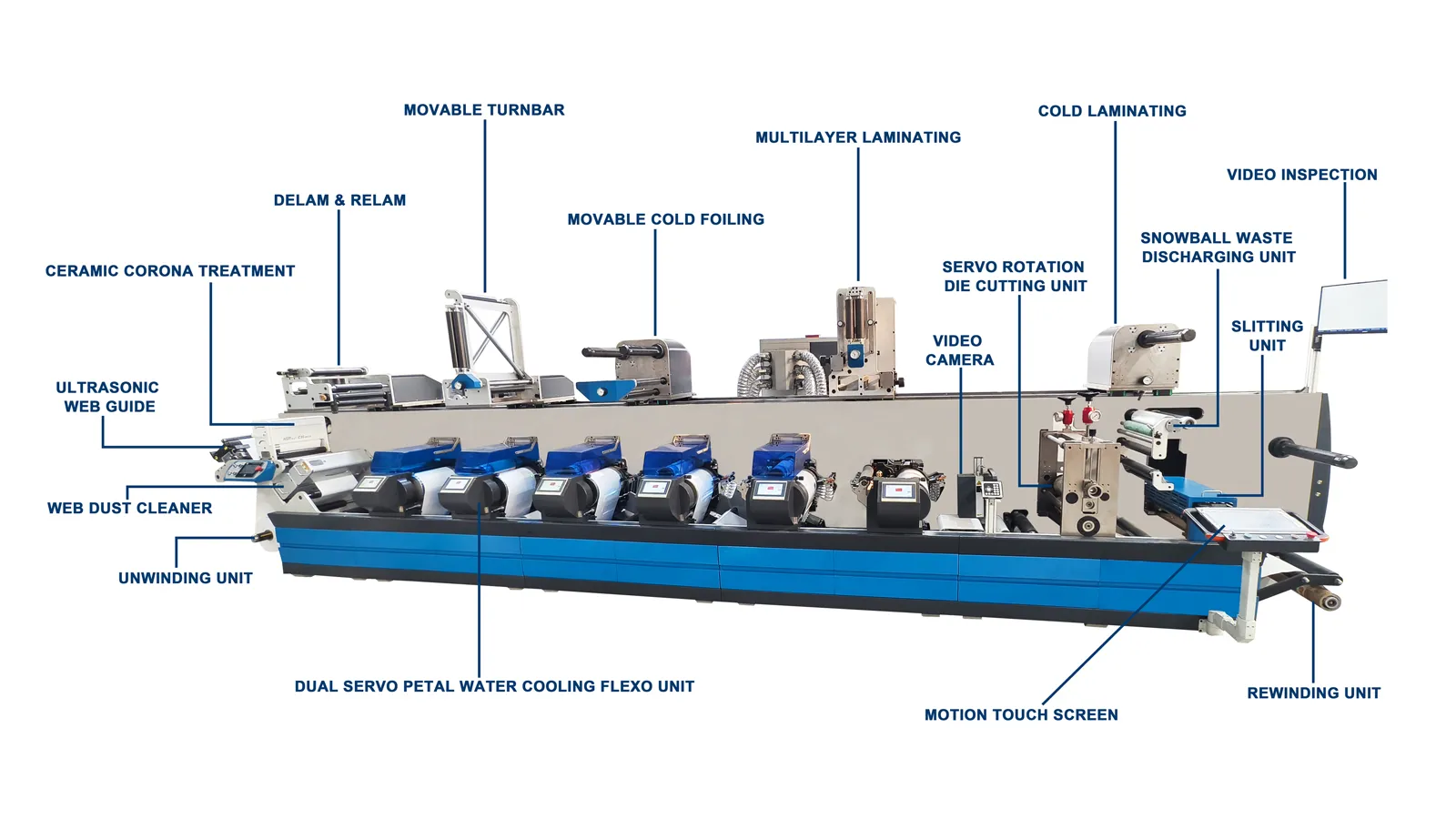

Product Overview: Premium Unit-Type Flexo Press

The NJZ-370B-6C represents the cutting edge of label printing technology. Unlike standard stack-type machines, this 6-Color Unit Type Flexo Printing Machine features a modular horizontal design equipped with Full Servo Motor Technology. It is specifically engineered for high-end converters who demand uncompromising print quality for Self-Adhesive Labels, Shrink Sleeves, and In-Mold Labels (IML). Its short web path design drastically reduces material waste during setup, maximizing your profitability.

Key Features & Technological Edge

- Full Servo Control System: The machine utilizes advanced servo motors to drive each print unit independently. This ensures ultra-precise tension control, allowing for stable printing on difficult materials like thin films and IML substrates.

- Unit Type Architecture: The modular "Unit" design provides superior stability and drying capability (UV/IR) between colors, enabling higher speeds and sharper dot reproduction than stack presses.

- IML (In-Mold Labeling) Ready: Specifically optimized to handle the delicate tension requirements of IML materials, giving you a competitive edge in the food packaging market.

- Short Web Path Design: Engineered to minimize waste. The distance between print stations is optimized to save meters of expensive material during job changeovers.

- Advanced Automation: Features automatic register capability and pre-registration memory, significantly reducing operator workload and setup time.

Target Applications

The NJZ-370B is the ultimate solution for:

- Premium Beverage Labels: High-quality wine, spirit, and juice labels.

- In-Mold Labels (IML): For PP/PE blow-molded containers and injection molding.

- Shrink Sleeves: PVC/PET shrink films for bottles.

- Cosmetic & Pharmaceutical Labels: Where fine text and complex graphics are required.

Upgrade to Servo Technology: Contact Newtop Machinery to request a demo video and specification sheet for the NJZ-370B.