Technical Specifications

Note: This machine is a customized model developed for one of our clients. Detailed specifications are not publicly disclosed. Please contact us for complete specifications, pricing, and operation videos.

Product Description

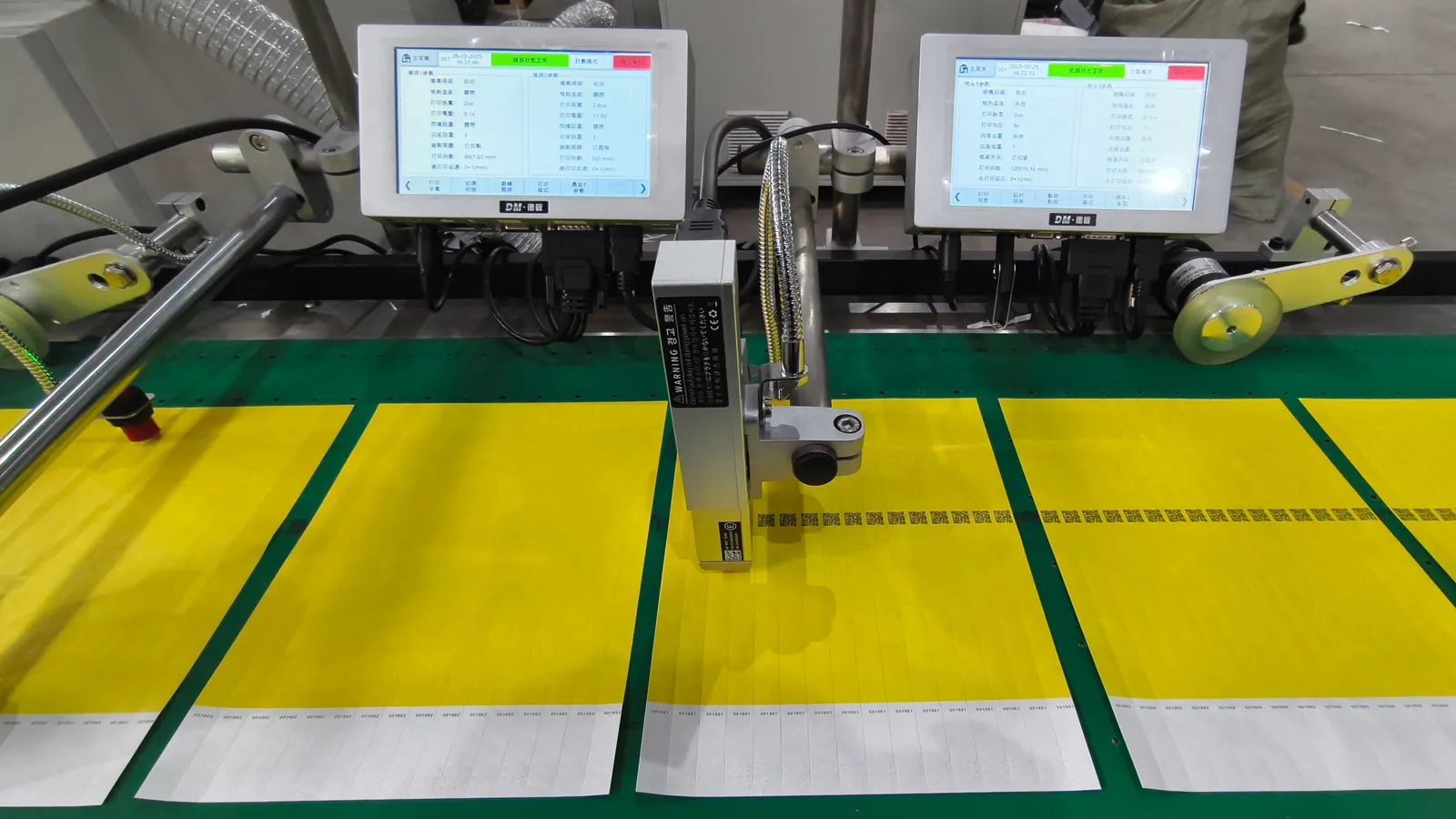

Product Overview: Specialized Solution for Wristband Production

The NRY-320AW is a dedicated industrial solution engineered for the high-volume production of identification wristbands. Whether you are manufacturing Medical Patient ID Bands or Event Admission Wristbands, this machine offers the perfect balance of speed and precision. While available as a standard printing unit, it can be fully customized into an integrated Paper Wristband Die Cutting & Printing Machine, allowing you to print, shape, and die-cut finished wristbands in a continuous Roll-to-Roll process.

Key Features & Customization

- Roll-to-Roll Efficiency: Designed for continuous operation, making it ideal for large-scale manufacturing of disposable paper and synthetic wristbands.

- Flexible Configurations: The base model starts with single-color printing, but we can configure it with Multi-Color Stations (up to 4-6 colors) and Inline Die-Cutting Units to meet your specific design needs.

- Material Compatibility: Perfectly suited for printing on various substrates, including Thermal Paper, Coated Paper, and Tyvek (Synthetic Paper), ensuring durable and water-resistant prints.

- Precision Registration: Essential for wristbands that require accurate alignment of barcodes, QR codes, and logos within a small printing area.

Industry Applications

The NRY-320AW is the preferred choice for manufacturers supplying:

- Healthcare: Hospital patient ID wristbands (Mother-Infant bands).

- Events & Leisure: Waterproof wristbands for Amusement Parks, Concerts, and Festivals.

- Security: Tamper-evident VIP access bands.

Request a Custom Proposal: Contact Newtop Machinery to discuss your specific wristband dimensions and printing requirements.