Technical Specifications

| Machine model | NJZ-330B | NJZ-420B |

| Machine color quantities | 1-9 colors | 1-9 colors |

| Maximum printing width | 320mm | 420mm |

| Maximum web width | 330mm | 430mm |

| Maximum unwinding diameter | 700mm (can be customized) | |

| Maximum rewinding diameter | 700mm (can be customized) | |

| repeat printing length | 250-600mm(10”-24”) | |

| Maximum printing speed | 120-150m/min | |

| Registering precision | ±0.1mm | |

| Die cutting station | one station | |

| Fast changing ink system | Quick change of ink tank | |

| Turn bar | Movable | |

| Voltage | 380V/3phases | |

| Plate Thickness | 1.7mm(also can do 1.14mm) | |

Product Description

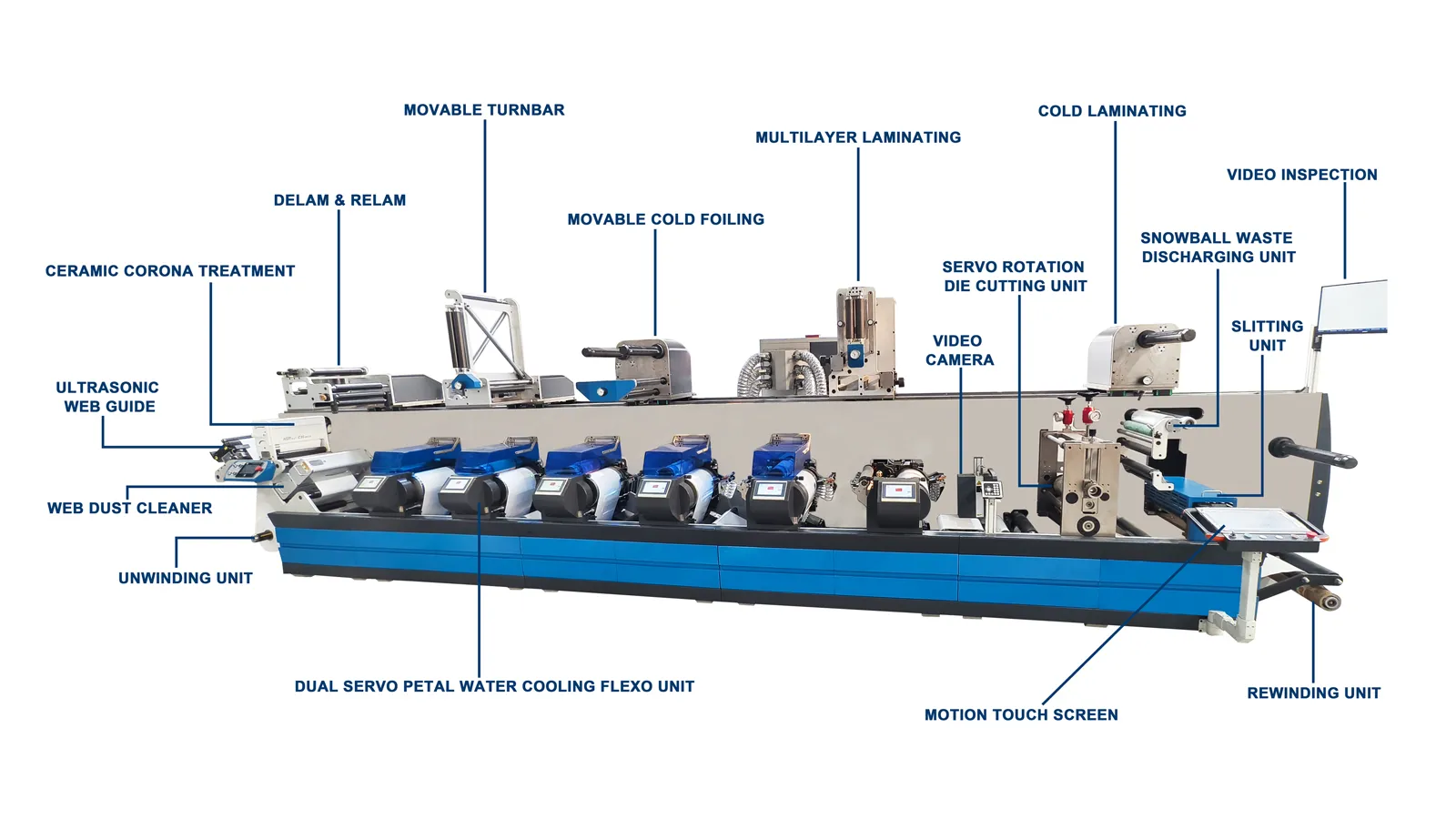

Product Overview: The All-Servo Solution for Film & Labels

The NJZ-420B is a state-of-the-art Full Servo Flexo Printing Machine designed for versatility and precision. With a wider printing width of 420mm, this machine bridges the gap between narrow-web label printing and mid-web flexible packaging. Powered by an independent servo motor for each print station (Petal-type structure), it delivers exceptional registration accuracy, making it the perfect choice for printing on difficult substrates like BOPP, PET, PVC shrink films, and Thermal Paper.

Key Features & Technical Highlights

- Independent Servo Drive System: Each printing unit is driven by its own servo motor. This eliminates gear marks and vibration, ensuring perfect color registration (±0.1mm) even on stretchable film materials.

- Short Web Path Design: The optimized machine layout significantly shortens the distance from unwinding to rewinding. This minimizes material waste during startup and job changes, saving you money on expensive substrates like foil and film.

- High-Speed Production: Capable of running at speeds up to 150 meters/minute, ensuring high output for large-volume orders of bottle labels or ATM paper rolls.

- Versatile Ink & Drying: Compatible with both Water-based inks (eco-friendly) and UV inks. The machine supports customized drying combinations (Hot Air / UV Curing) to suit different materials.

- Integrated Finishing: This "All-in-One" solution can handle Feeding, Printing, Varnishing, Drying, Laminating, Die-Cutting, and Rewinding in a single pass.

Optimized Applications

The NJZ-420B excels in handling diverse materials from 20g to 250g:

- Unsupported Films: BOPP, PET, PVC, PE films (wrappers, shrink sleeves).

- Self-Adhesive Labels: Top-grade stickers for food, beverage, and cosmetics.

- Specialty Paper: Thermal paper (ATM rolls), Kraft paper, and Clothing tags.

Request a Technical Proposal: Contact Newtop Machinery to learn how the NJZ-420B can expand your product range into flexible packaging.