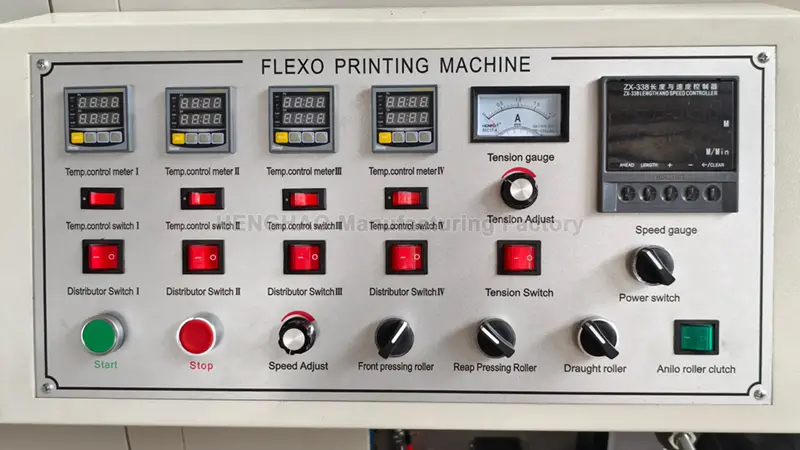

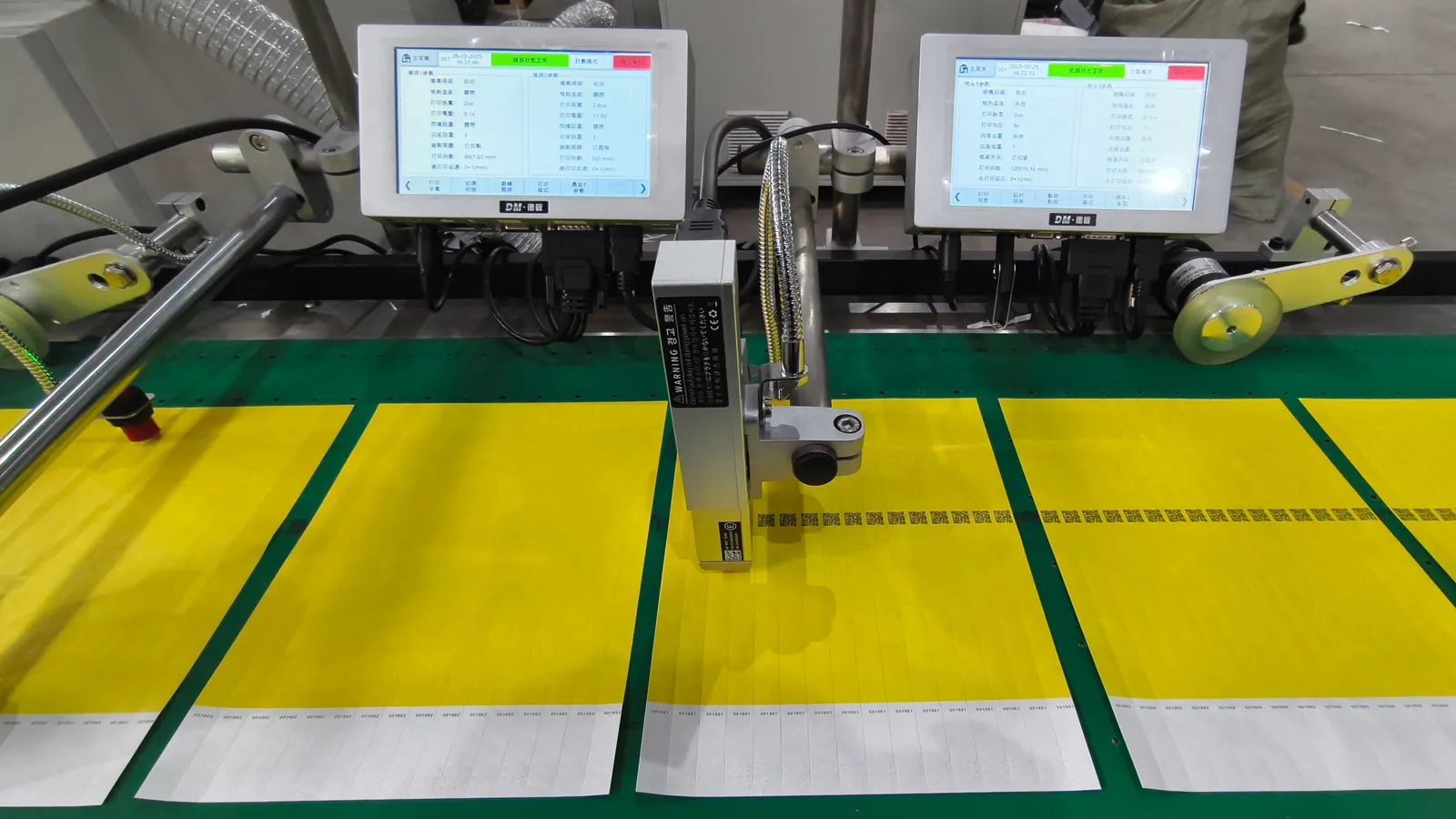

Engineered for industrial Mass Production, Newtop's Stack Type Flexo Printing Machines define efficiency in the Roll-to-Roll printing sector. Unlike standard entry-level models, our High-Speed Series is built with heavy-duty frames and precision transmission systems, ensuring stable continuous operation for 24/7 heavy-duty production schedules.

This series is the ultimate solution for manufacturers of Self-Adhesive Labels, Paper Cups, and Kraft Paper Bags. Whether you require a narrow web (320mm) for stickers or a wide web (1300mm) for shopping bags, our machines deliver exceptional color consistency and ink drying performance at speeds up to 120 m/min, helping you maximize output and profitability.