World-Class Aluminum Foil Packaging Solutions by MTED

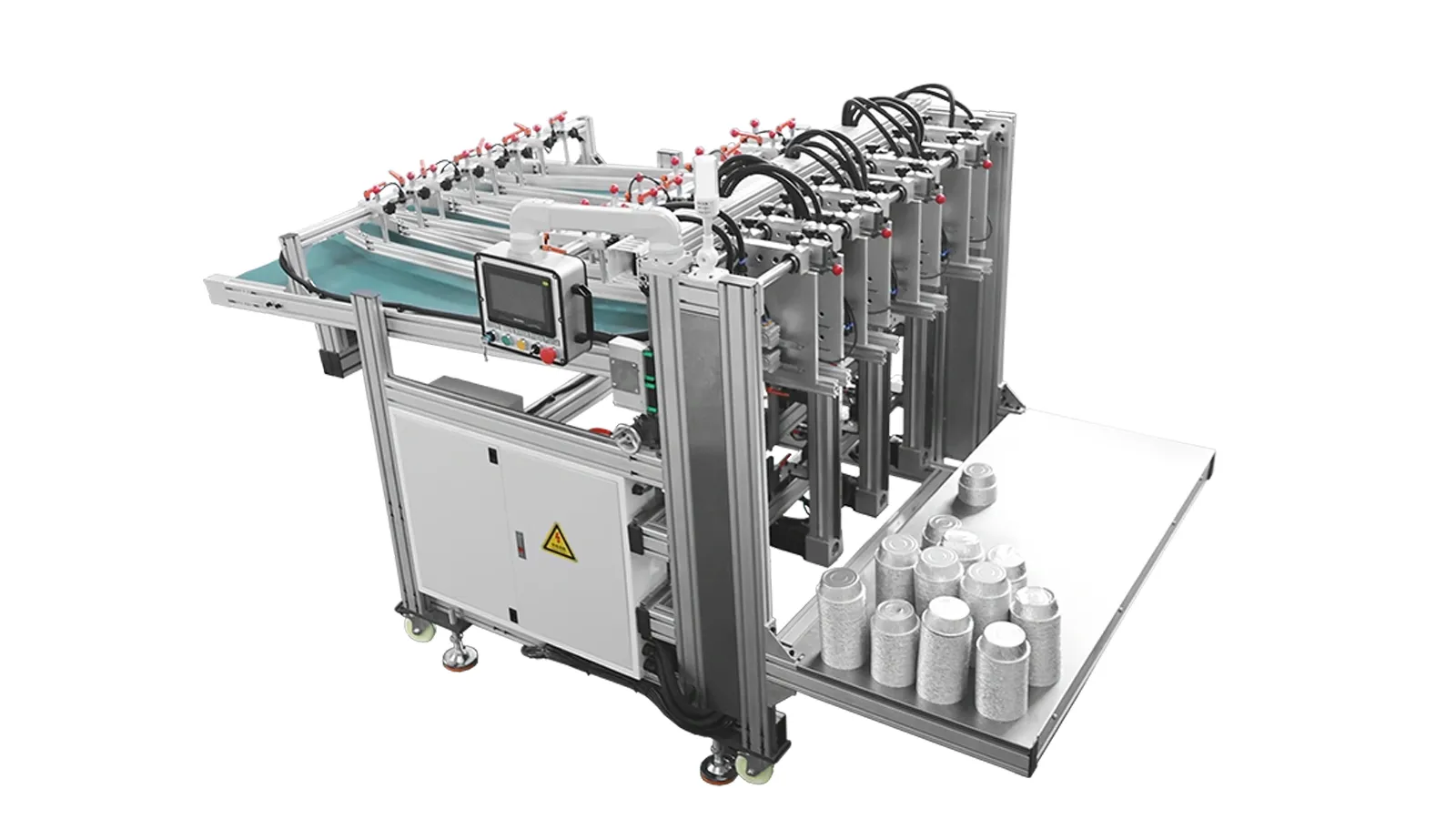

We are proud to present the MTED RZLH Series of Aluminum Foil Container Making Machines. These fully integrated production lines are designed to meet the growing global demand for hygienic, environmentally friendly, and high-quality aluminum packaging. From wrinkle-free airline food trays to standard takeaway lunch boxes, MTED machines deliver precision and high-speed output.

Manufacturer Information:

Brand: MTED

Website: mtedmachinery.com

Email: [email protected]

WhatsApp: +8619883709253