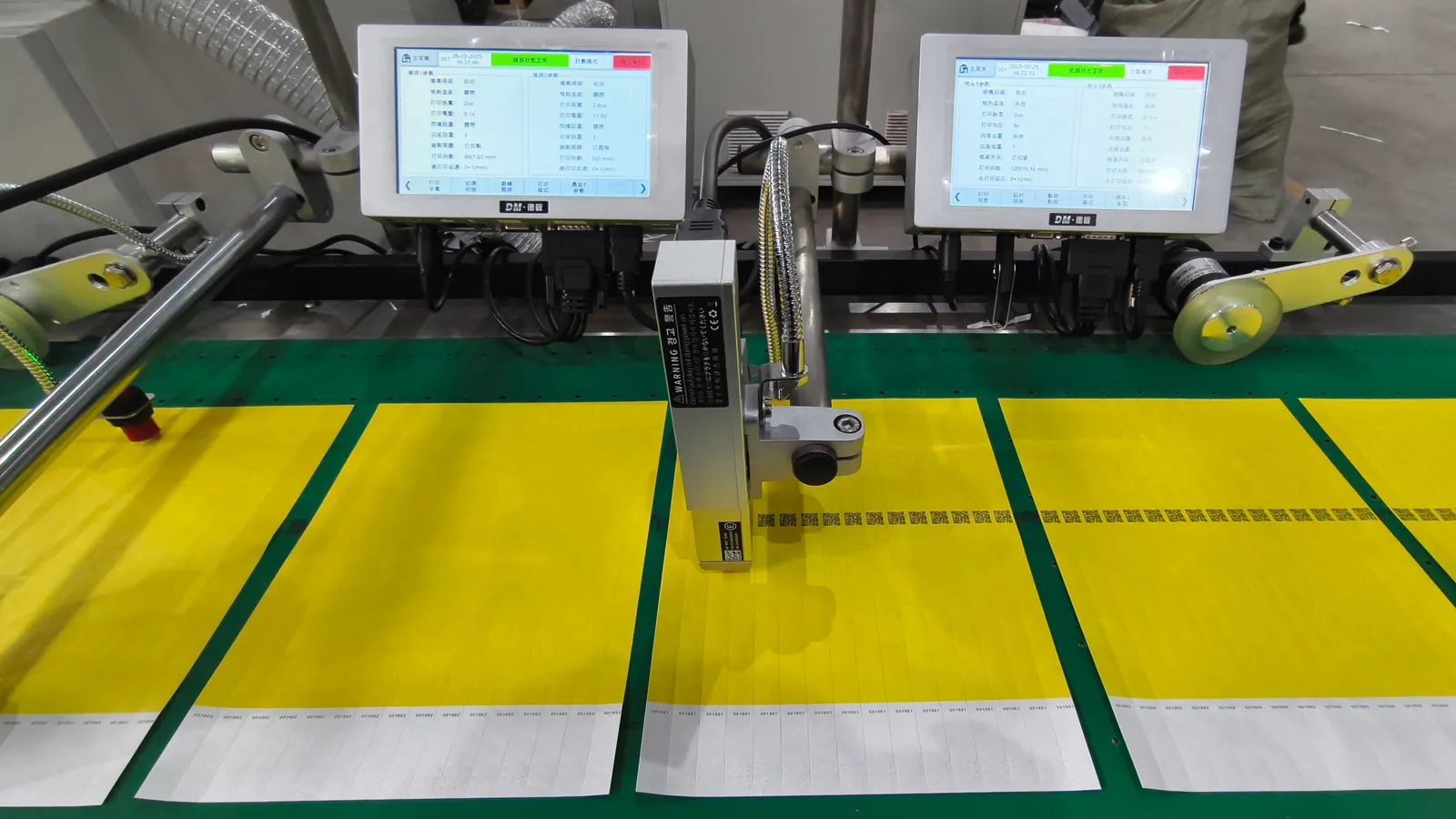

NTPCQ-850A Paper Cup blanks Punching Die Cutting Machine

- Model: NTPCQ-850A

- Paper Cup Fans Punching

- Maximum Paper Width: 850mm

- Max Cutting Area: 380*850mm

- Production Capacity: 150-200 times/min

- Integrable with Paper Cup Printing Machine

- Customizable to your needs

(117)