Speed and Efficiency for Mass Production.

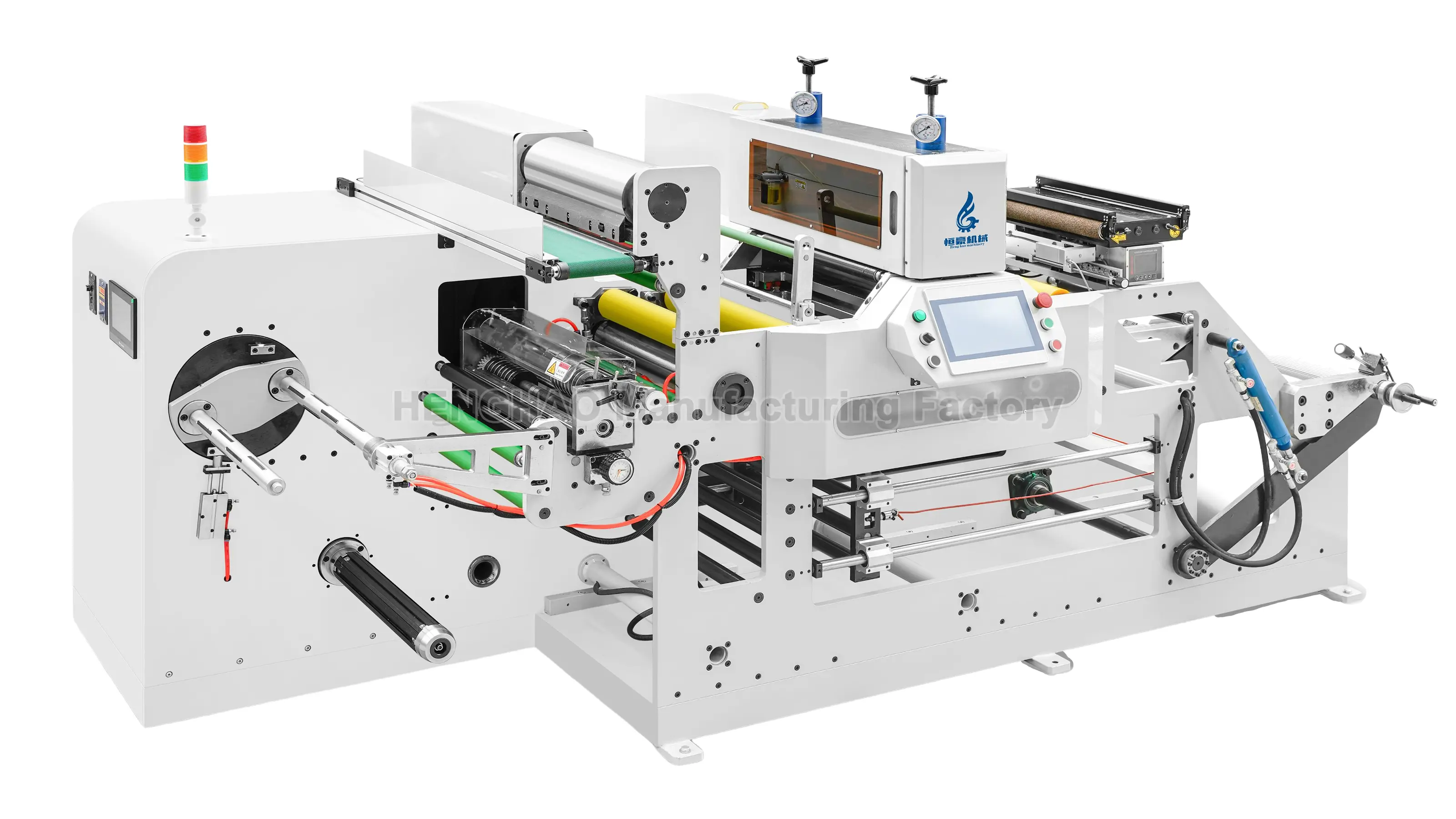

For label converters handling large volumes of blank labels, thermal transfer labels, and logistics tags, speed is the ultimate currency. Newtop’s Rotary Die Cutting Machines are the workhorses of the finishing department, engineered to operate on a fully rotary principle for continuous, high-speed converting.

Unlike intermittent systems, our rotary converters offer smooth, continuous web movement, allowing for production speeds of up to 150 meters/minute (and higher depending on configuration). They are designed to be more than just die cutters; they are complete finishing lines.