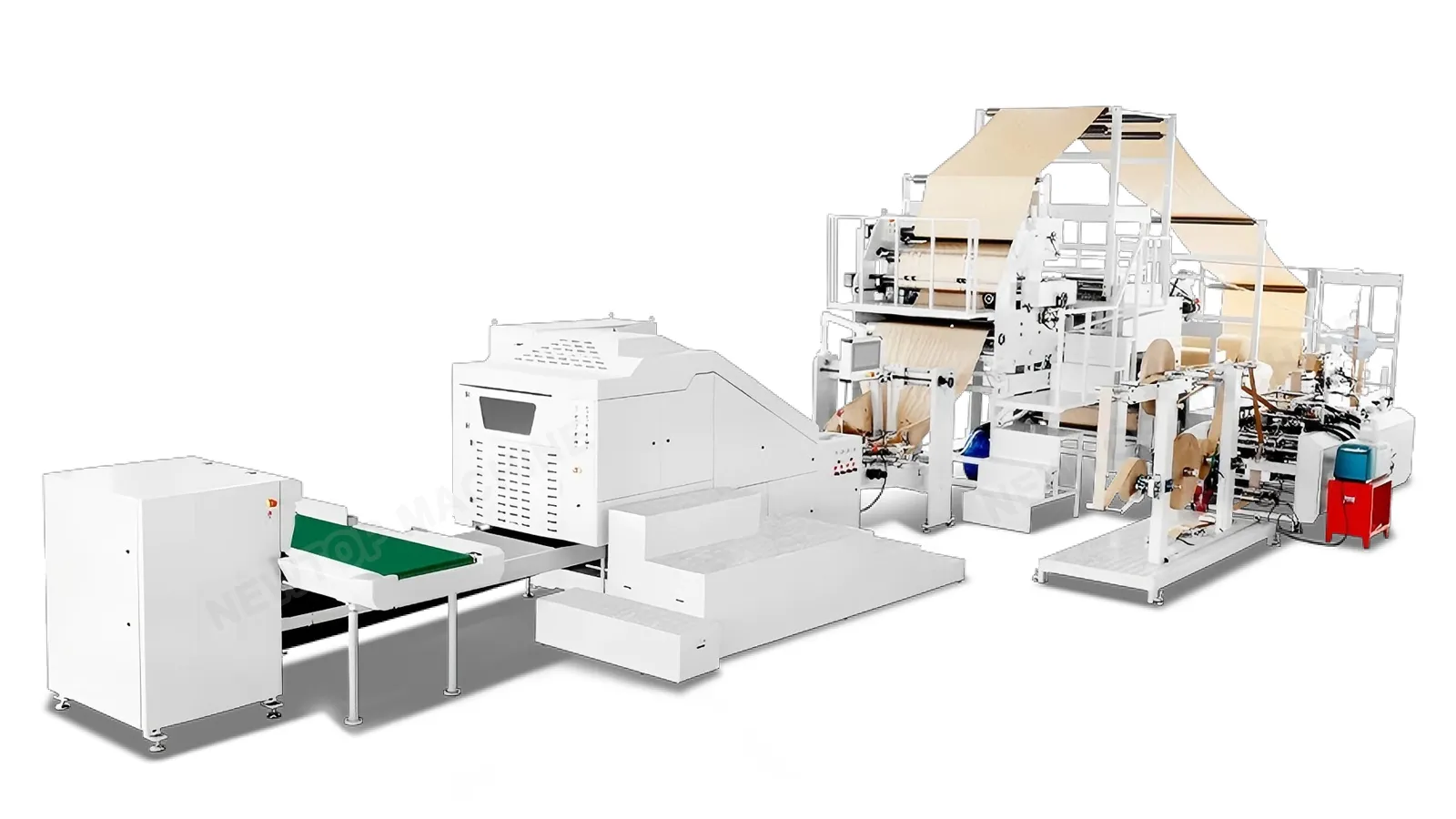

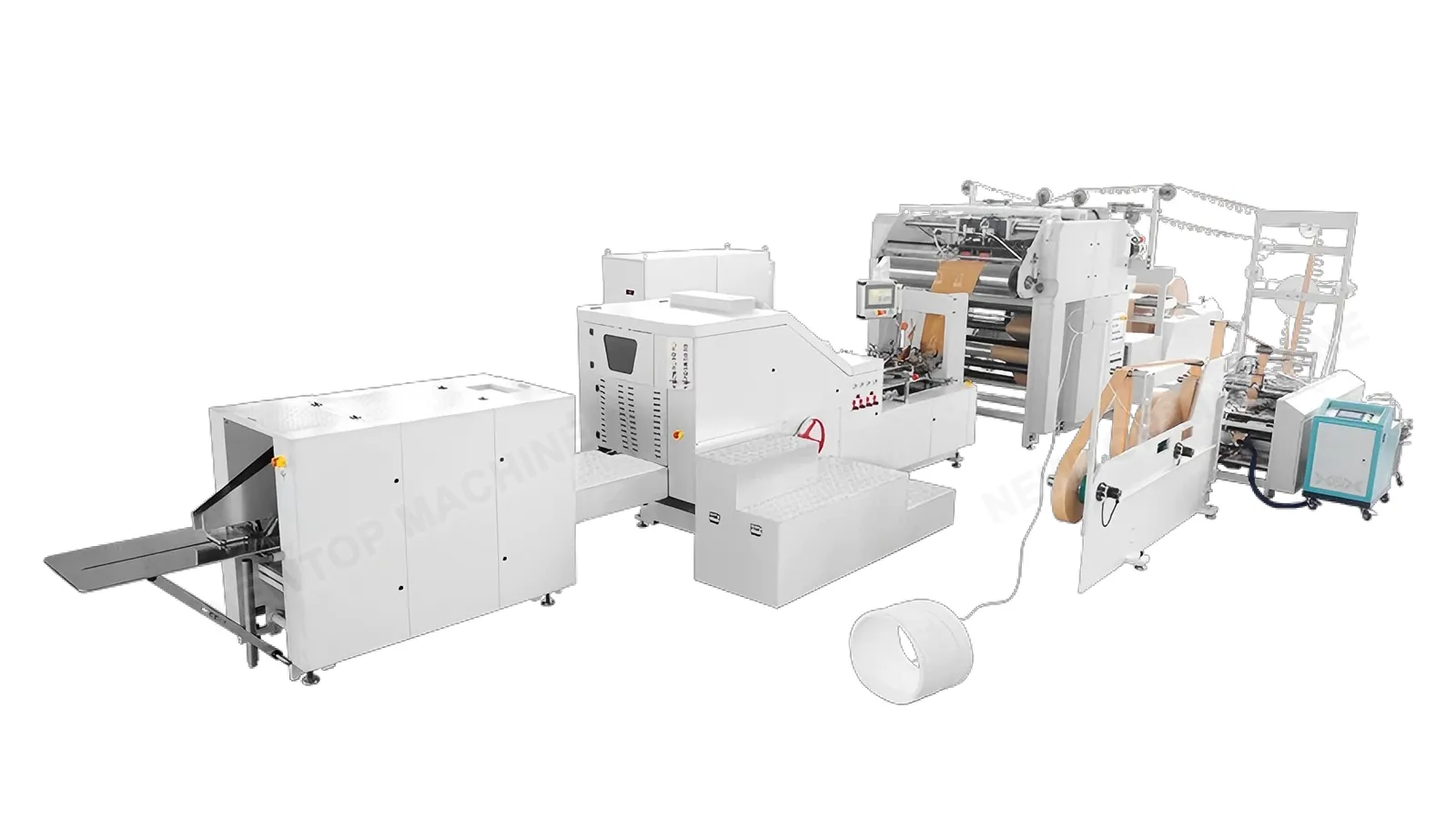

NTPFD-250T Fully Automatic Square Bottom Paper Bag Machine with Twisted Handle

- Model: NTPFD-250T

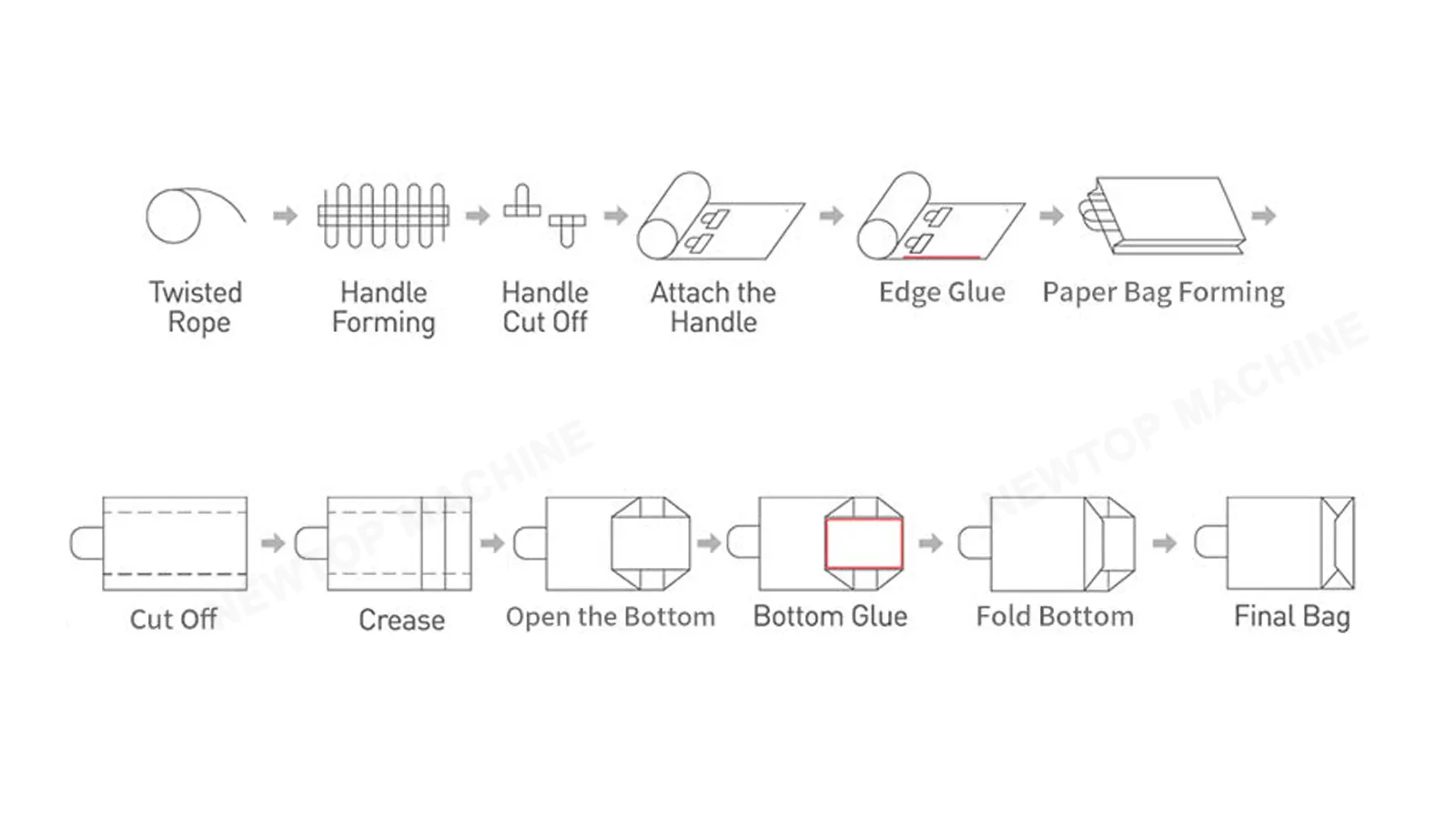

- Function: Bag Making + Twisted Handle Inline

- Bag Width: 110-250mm

- Cutting Length: 240-470mm

- Bottom Width: 60-150mm

- Paper Thickness: 80-150 gsm (For Handle)

- Mechanical Speed: 150 pcs/min

- Handle Type: Twisted Rope Handle

- Total Power: 41.5 KW

- Machine Weight: 15,000 kg

(579)