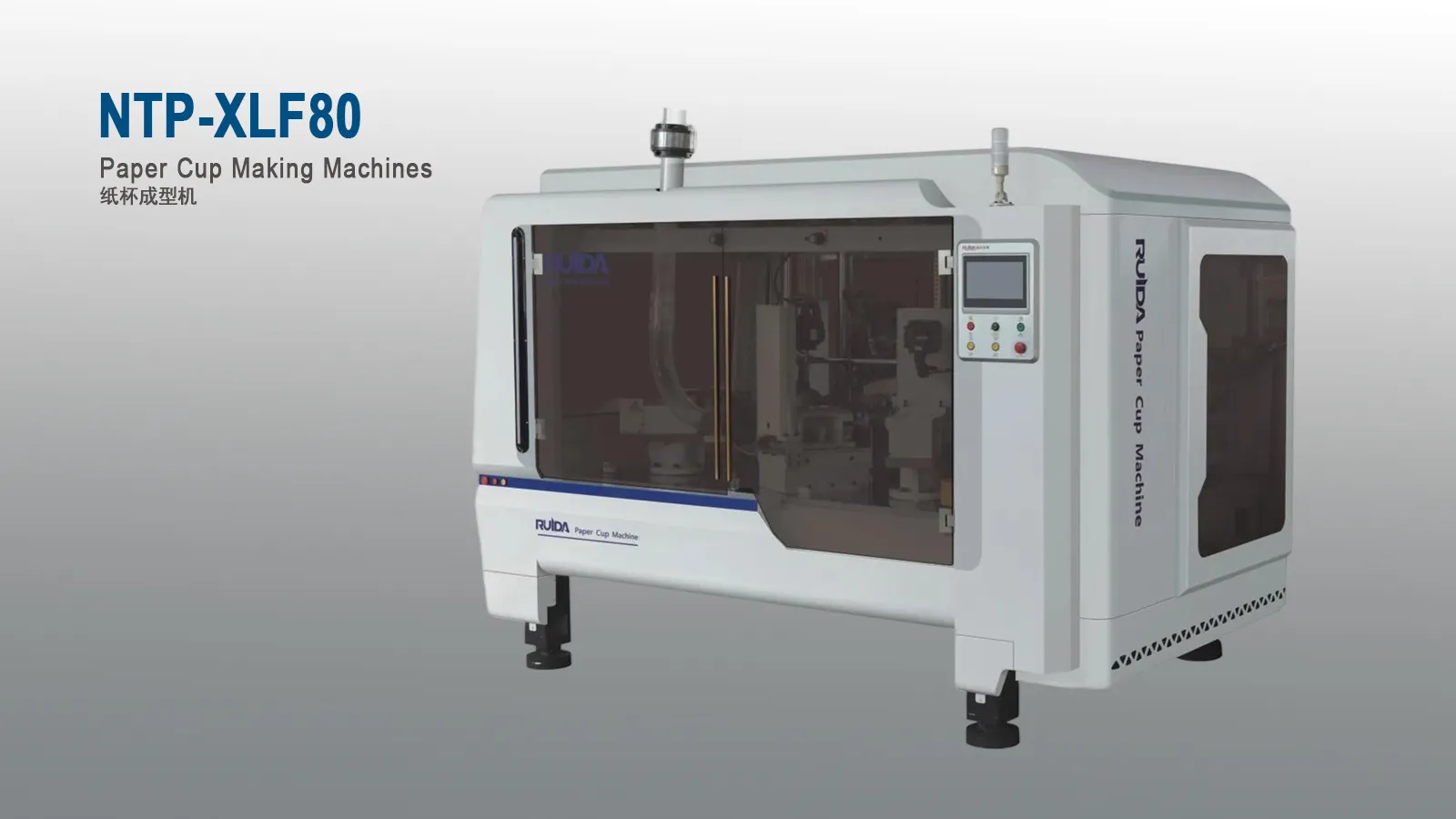

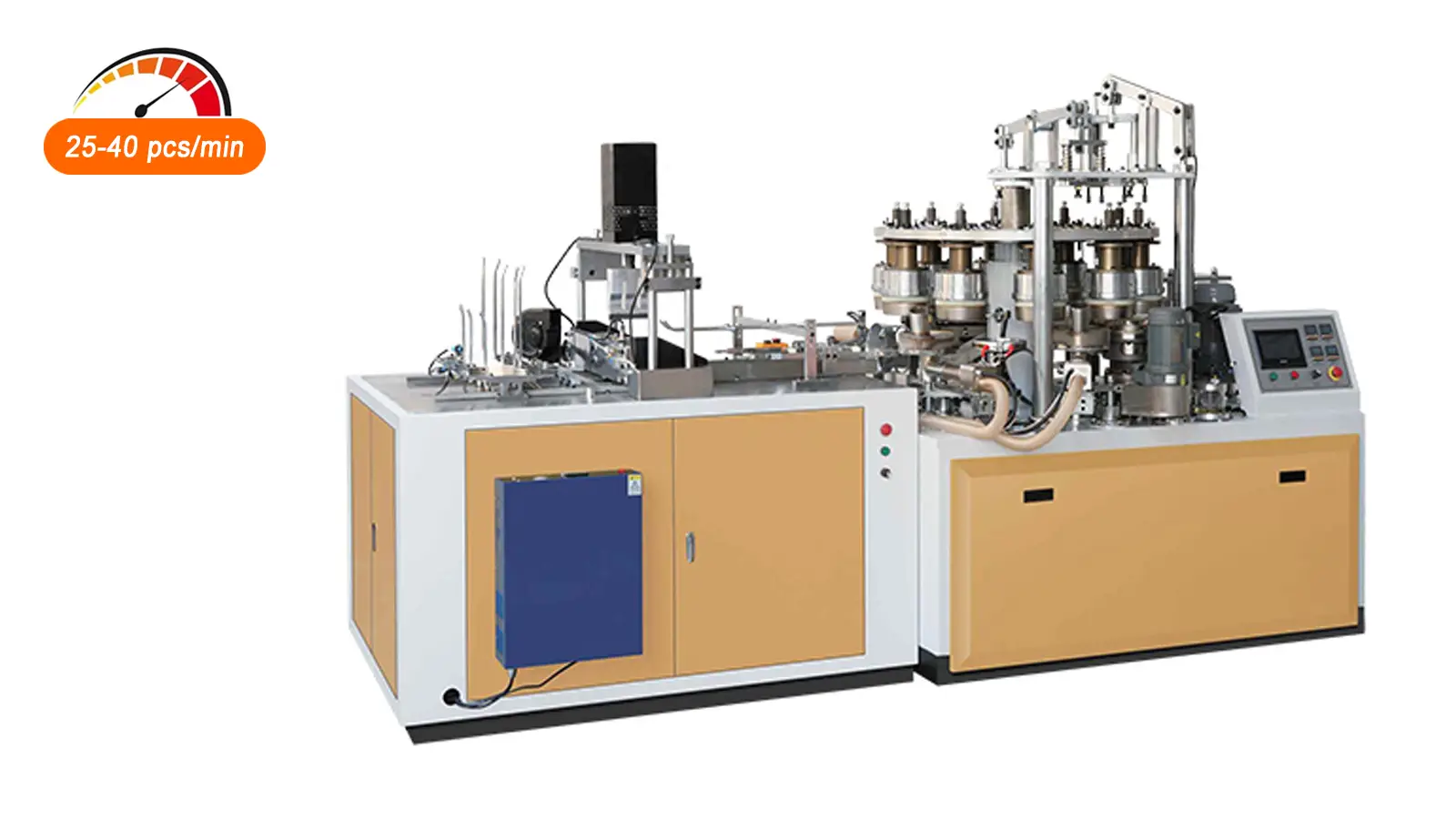

Vertical High Speed Paper Cup Machine - NTP-100A | 160pcs/min Dual Turntable

- Speed: 120–160 pcs/min

- Size Range: 4–22 oz paper cups

- Single & Double PE-Coated Paper

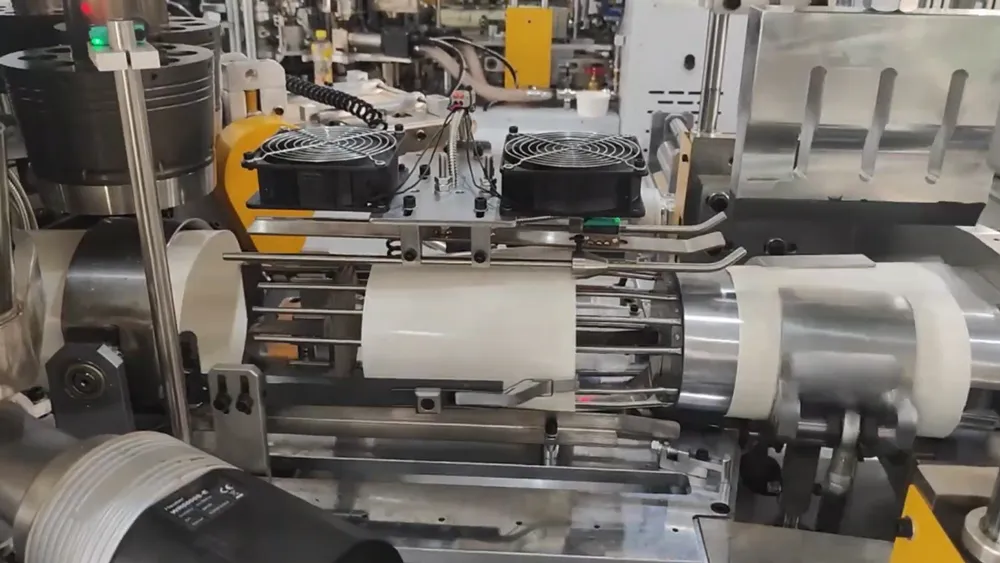

- Dual Swiss Leister Hot Air

- PLC + Servo + Photoelectric Monitoring

(876)