Technical Specifications

| Model | NTP-TM420 |

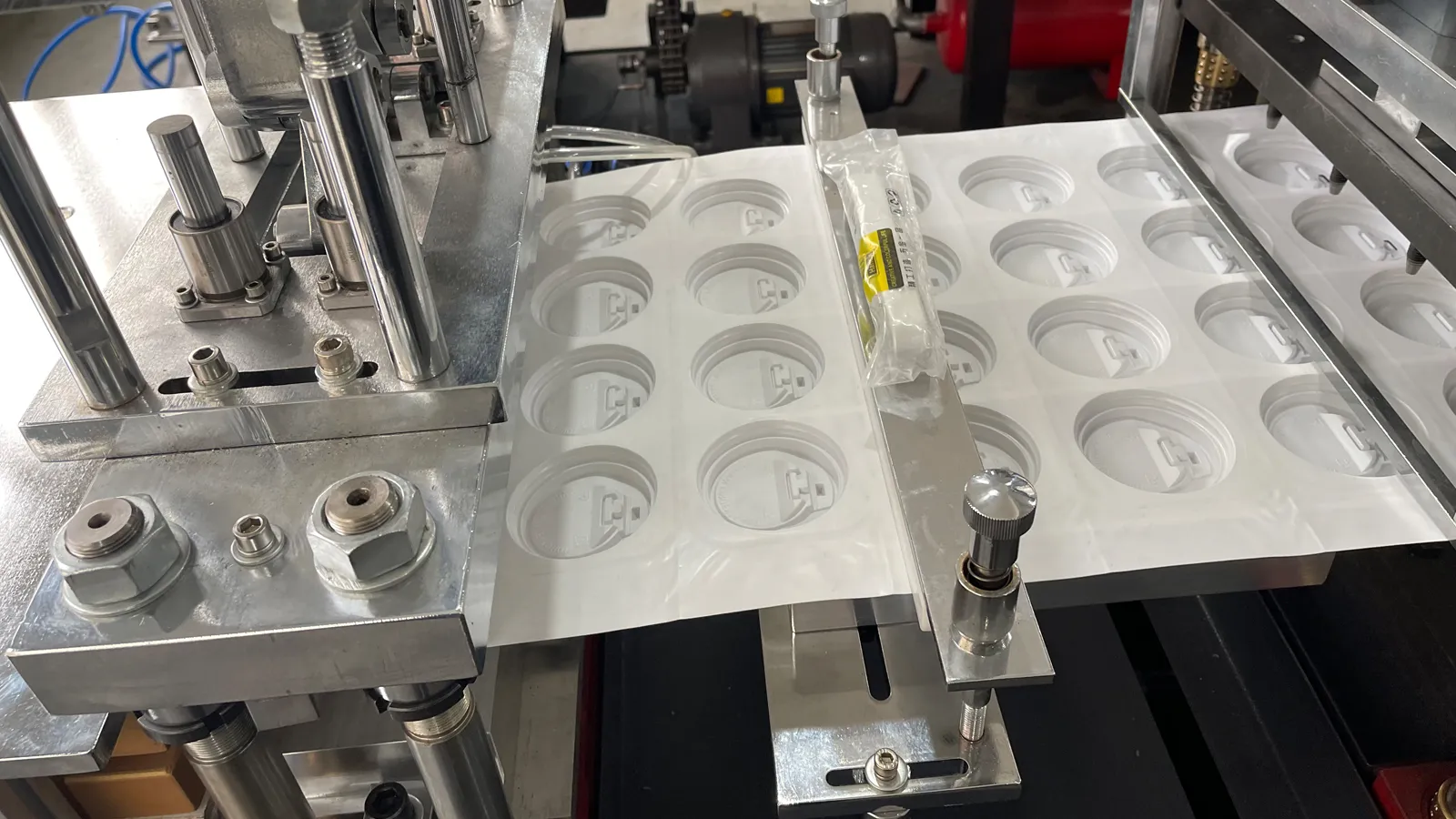

| Max Forming Area | 420mm x 160mm |

| Max Forming Depth | 45mm |

| Cutting Frequency | 15 - 45 Times/Min |

| Stroke Range | 180mm (Adjustable) |

| Motor Power | 1.5 kW |

| Air Consumption | >0.2 m³/min |

| Air Pressure | 0.4 - 0.7 MPa |

| Power Supply | 380V / 220V / 50Hz |

| Overall Dimensions | 2500 x 1000 x 1600 mm |

| Weight | 1350 kg |

Product Description

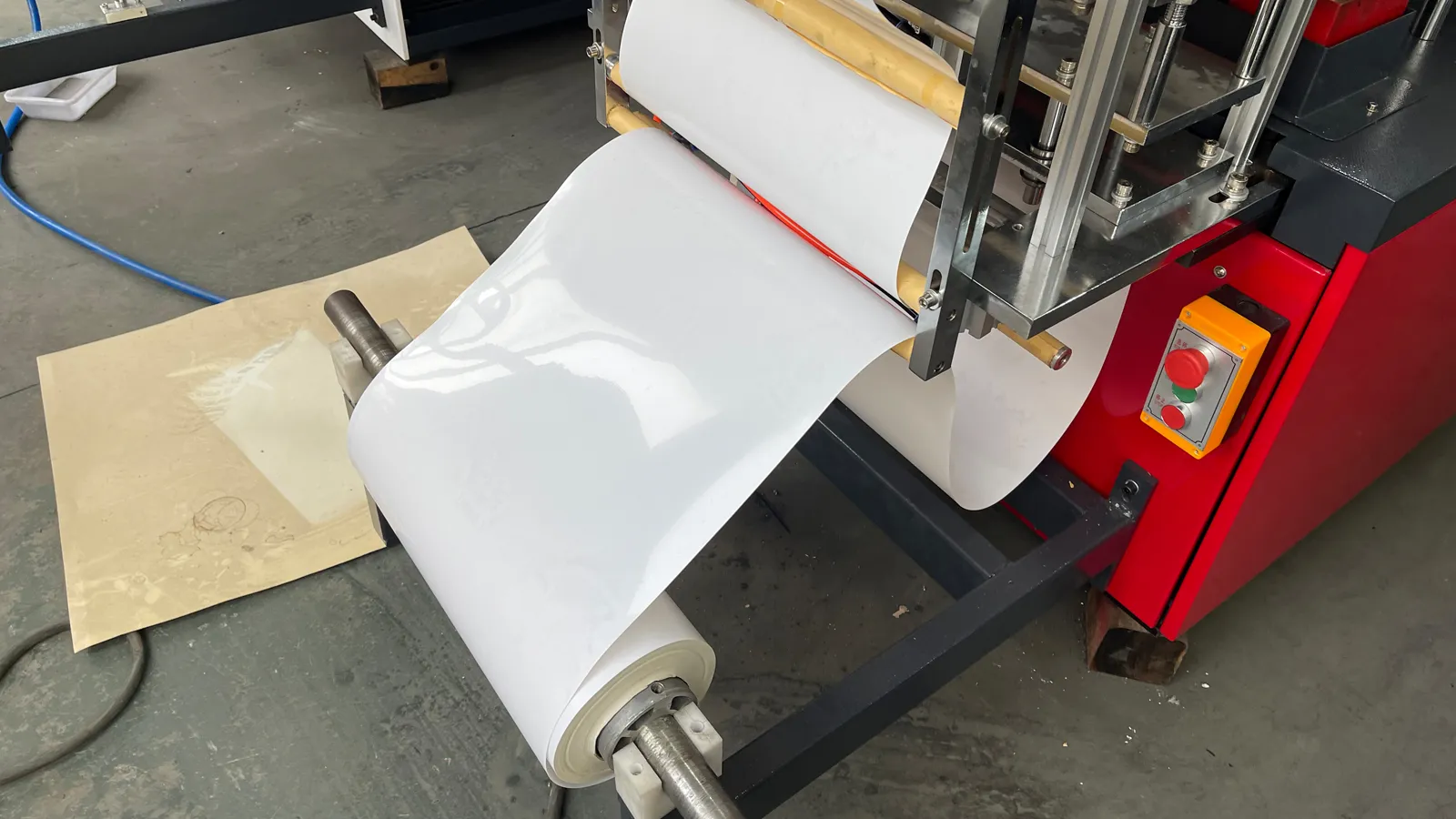

The NTP-TM420 Automatic Plastic Cup Cover Forming Machine is the ideal solution for manufacturers seeking a balance between performance and footprint. Designed as a compact, fully automated workhorse, this machine specializes in the production of plastic lids for coffee cups, ice cream bowls, and pharmaceutical packaging.

Compact "All-in-One" Design

Space is money. The NTP-TM420 features a smart, consolidated layout that integrates feeding, heating, forming, and cutting into a footprint of just 2.5 meters. Unlike bulky traditional lines, this machine fits easily into smaller workshops or crowded production floors without sacrificing output capacity.

Servo-Driven Precision & Efficiency

Don't let the size fool you. The NTP-TM420 is equipped with an advanced Servo Motor Feeding System. This ensures:

- Smooth Operation: Eliminates the vibration found in mechanical cam machines.

- Material Savings: Precise step control reduces the skeleton scrap web to the absolute minimum.

- Energy Efficiency: Operating with a motor power of just 1.5kW, it significantly lowers your daily electricity costs compared to larger hydraulic systems.

Safety & Hygiene First

The machine comes standard with a Fully Enclosed Safety Guarding System. This not only complies with rigorous international safety standards to protect operators but also creates a sanitary environment for food packaging production, keeping dust and contaminants away from the forming area.

Perfect for Startups & Specialty Runs

Need to produce 15,000 - 45,000 lids per hour with minimal investment?