Technical Specifications

| Model | NTP-TM450 |

| Forming Area (Max) | 450mm x 150mm |

| Forming Depth (Max) | 30mm (Standard) |

| Production Speed | 15 - 35 Cycles/Min |

| Suitable Materials | PET, PLA, PS, PVC, HIPS |

| Sheet Thickness | 0.15 - 0.50 mm |

| Air Pressure | 0.6 - 0.8 MPa |

| Air Consumption | 0.8 m³/min |

| Total Power | Approx. 18 kW (380V / 50Hz) |

| Machine Dimensions | 2800 x 1100 x 1600 mm |

| Weight | 2,000 kg |

Product Description

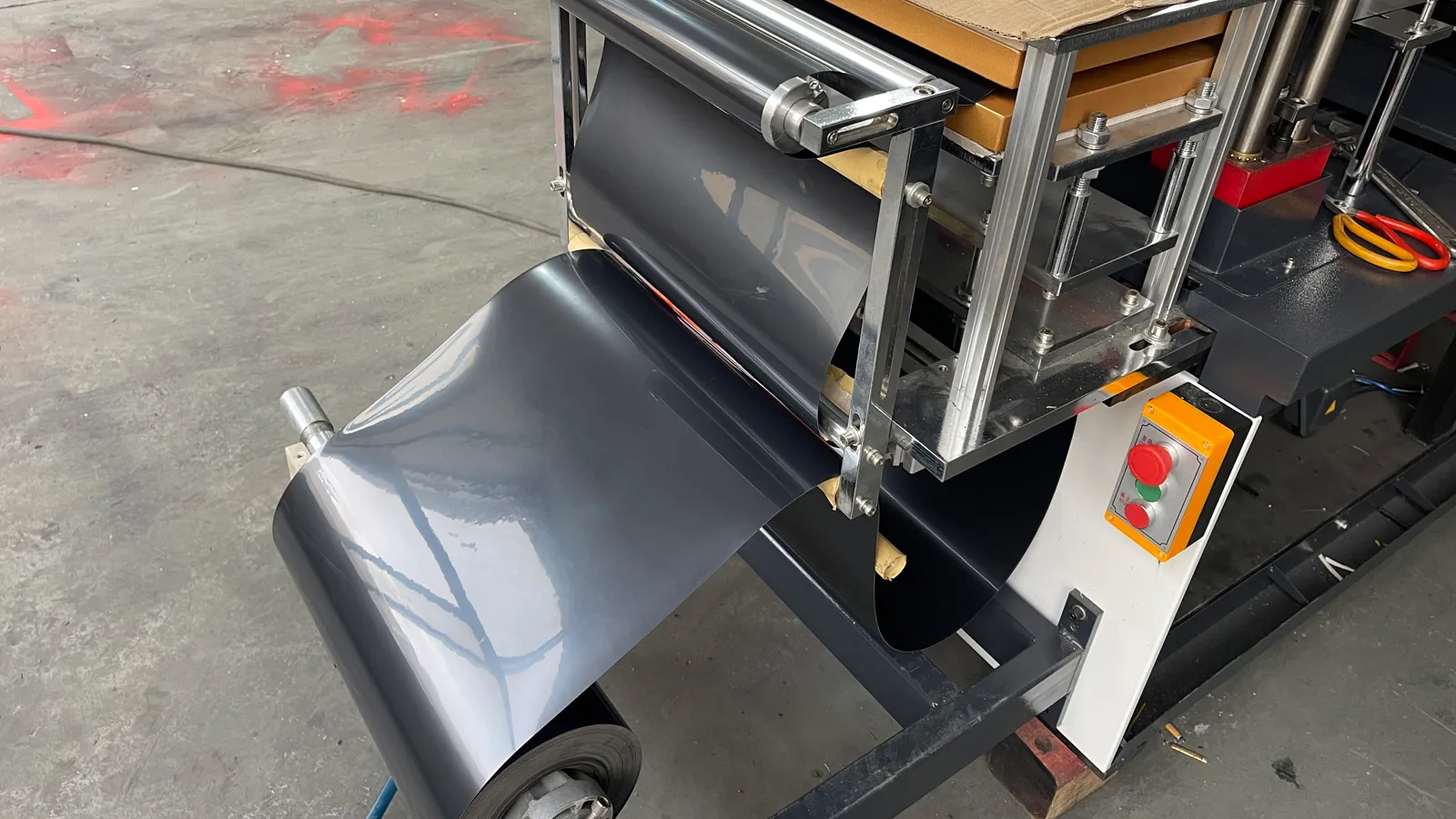

The NTP TM450 Automatic Cup Lid Forming Machine represents the next generation of thermoforming technology. Designed specifically for the high-volume production of disposable plastic lids, this "All-in-One" solution integrates material feeding, heating, forming, punching, and scrap winding into a single, compact unit.

Whether you are producing hot coffee lids, cold drink dome lids, or salad bowl covers, the NTP TM450 delivers hospital-grade hygiene and industry-leading precision. It is the preferred choice for manufacturers transitioning to modern, eco-friendly materials like PET and PLA.

1. Precision Forming: The Secret to Leak-Proof Lids

In the beverage packaging industry, the "Snap-Fit" is everything. A loose lid means spills and customer complaints. The NTP TM450 moves beyond traditional vacuum forming by utilizing a Positive & Negative Pressure System. By applying compressed air from above and vacuum from below, the machine forces the plastic sheet into every microscopic detail of the mold.

The result is a lid with:

- Sharper Undercuts: Ensuring a tight, secure lock on the cup rim.

- Defined Details: Clear logos and perfectly punched sip holes.

- Structural Rigidity: Stronger lids even when using thinner materials.

2. Crystal Clear PET & Biodegradable PLA Processing

Processing advanced materials requires precise thermal management. The NTP TM450 is equipped with a German-engineered PID Segmented Temperature Control System. This technology solves the two biggest headaches in lid production:

- For PET: It prevents crystallization (whitening), ensuring your dome lids remain 100% transparent and premium-looking.

- For PLA: It provides the gentle, uniform heat required to form biodegradable corn-starch materials without melting or warping.

3. GMP Hygienic Design & Labor-Saving Automation

Food safety is non-negotiable. The NTP TM450 is built to GMP (Good Manufacturing Practice) standards. All parts that come into contact with the product are made from Stainless Steel 304. Crucially, the machine features a "Clean Design" architecture that physically separates the lubrication/drive system from the forming area, guaranteeing zero oil contamination.

To maximize your profit margin, the machine supports full automation integration:

- Auto-Feeding: Smoothly handles heavy material rolls.

- Scrap Winding: Automatically collects waste web for easy recycling.

- Optional Auto-Stacker: Counts and stacks lids directly onto a conveyor, allowing one operator to supervise 2-3 machines simultaneously.

4. Versatile Applications

With a rapid mold change system, the NTP TM450 is versatile enough to produce a wide range of products:

- Coffee Lids: 80mm / 90mm (PS/PP)

- Dome Lids: Flat or Arched for Slushies/Smoothies (PET/PLA)

- Bowl Covers: For Paper Salad Bowls or Soup Containers

- Mini Portion Cups: Sauce or Condiment lids

Ready to Optimize Your Production?

Not sure which mold layout maximizes your output? Send us your lid sample or drawing.

Our engineering team will provide a Free Production Output Calculation and a custom mold design proposal within 24 hours.